PRODUCTS

1. Product introduction

GS sanitary stainless steel screw pump is a positive displacement pump. This pump can be used to transport neutral or corrosive liquids, clean or abrasive liquids, liquids containing gas or easy to generate bubbles, high viscosity or low viscosity liquids, including liquids containing fibers and solid substances. It can work for a long time and maintain stable flow, and has good self-priming capacity.

2. Product pictures

3. Scope of application

(1) Food industry: transportation of minced meat, potato salad, paste, concentrated fruit juice, jam, vegetable products.

(2) Brewing industry: transportation of distiller's grains, yeast, various fermented residues and ingredients.

(3) Sugar industry: syrup, saturated residue, concentrated wastewater residue, sugar crystal paste; Milk, cheese.

(4) Textile industry: conveying synthetic fiber liquid, viscose liquid, dye, ink, nylon powder liquid.

(5) Paper making industry: conveying pulp liquid, talc pulp, glazing resin pulp.

(6) Petroleum industry: transport a variety of oils, grease products, refinery sludge and industrial wastewater.

(7) Chemical industry: all kinds of emulsion, suspension, ointment, shampoo, paint, pigment.

(8) Construction industry: transportation of mortar, plaster, asphalt, tar, mortar and paint.

(9) Mining industry: transportation of oxides and wastewater, mine drainage, liquid and scum.

4. Product Features

(1) Both ends of the connecting shaft of sanitary screw pump adopt straight or refined universal joint, and its pin and pin sleeve are made of special materials, so its service life has been greatly improved, and its structure is simple and easy to disassemble.

(2) Both ends of the bushing are provided with wrapped rubber to ensure reliable sealing between the bushing and the inlet and outlet pipes. This ensures that the bushing body is not corroded.

(3) A replaceable stuffing box is installed between the suction pipe and the bearing, which can be used for both packing seal and mechanical seal (different forms of seal replacement can be carried out).

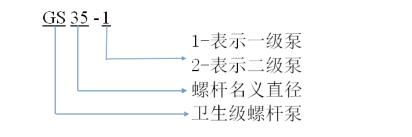

5. Model Meaning

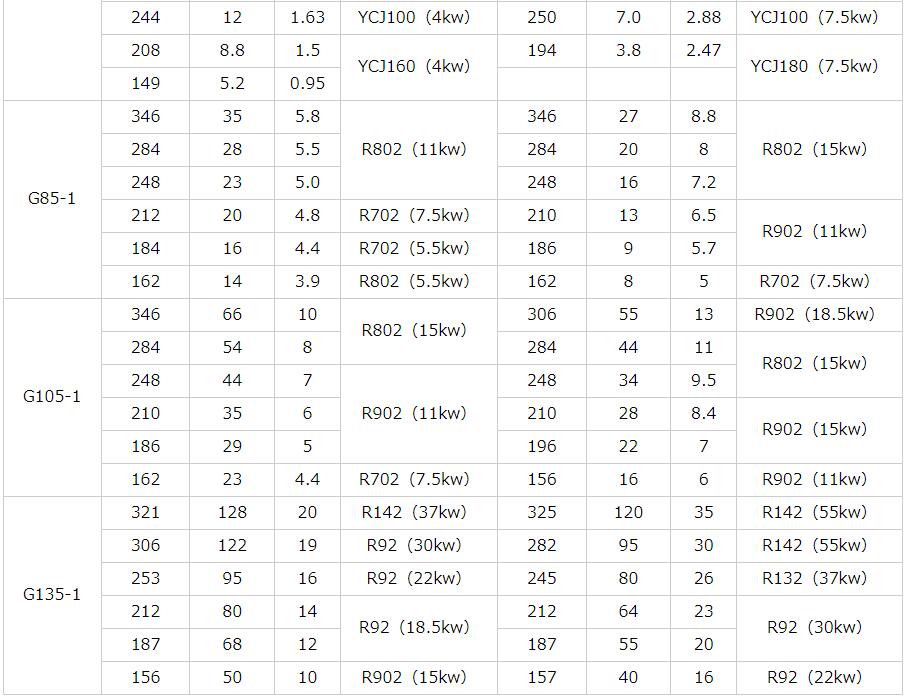

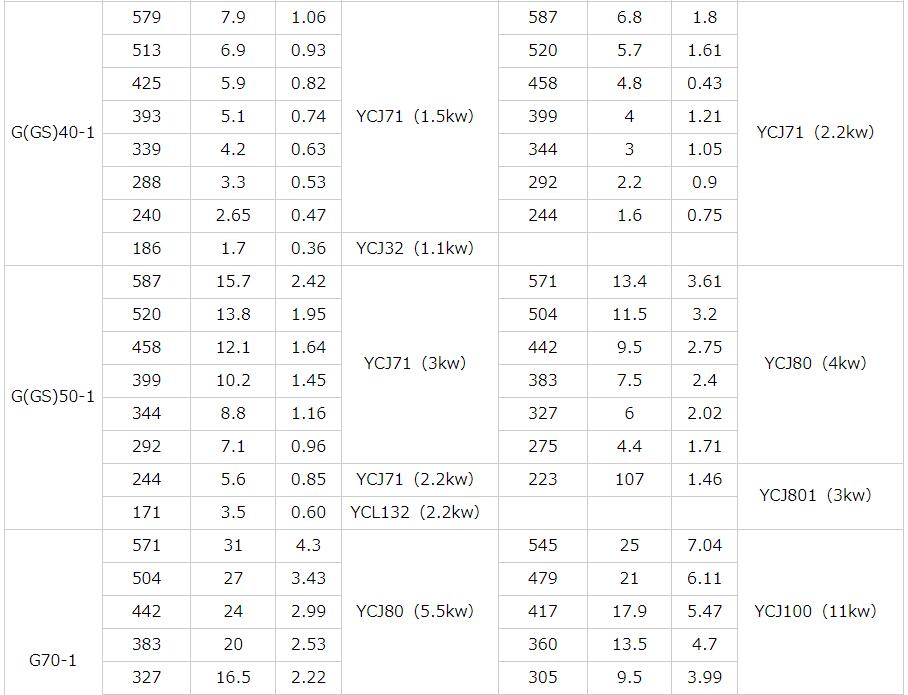

6. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

2. Medium under special working conditions

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) The pump, power machine and base have been adjusted and fixed before delivery. If the foundation is uneven during installation, the foundation will be twisted when the anchor bolts are tightened, causing the coupling center to shift. For this reason, the coupling guard shall be removed, and the coupling installation deviation shall be maintained: △ Y ≤ 0.2mm, △ a ≤ 30 '

(3) GS sanitary screw pump allows positive and negative rotation, and we recommend running counterclockwise (looking from the pump outlet shaft end)

(4) When the pump is connected with the pipeline system, a section of flexible pipe larger than the length of the stator shall be installed at the pump outlet to facilitate stator replacement or maintenance.

(5) The pipeline shall be cleaned in advance to prevent sundries from blocking or damaging the stator and rotor.

8. Precautions

(1) Before starting the sanitary screw pump, fill the liquid in advance and turn the gear to lubricate the stator.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) The unit operates for 5-10 minutes. If there is no abnormal phenomenon, it can be put into operation.

(4) When GS sanitary screw pump uses packing seal, it is necessary to check the leakage frequently and press the packing cover in time. It is better to drop a little medium. If the pressure is too tight, the packing and shaft will get hot and bite. Replace all worn packing rings.

9. Frequently Asked Questions

(1) There may be air in the pump chamber if the pump does not discharge water.

(2) Insufficient pump flow may be caused by partial blockage of pipes and impeller of pump flow passage, insufficient valve opening, etc.

(3) Excessive pump power may be used beyond the rated pressure.

(4) Noise and vibration may be caused by unstable pipeline support, excessive outlet pressure, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) The sanitary screw pump shall be cleaned regularly for transporting medium that is easy to settle and fix. Due to different conveying media and operation methods, the cleaning interval is determined by the operator.

(2) If the outlet pipeline is blocked or the valve is closed unexpectedly, the pressure of the pump will rise sharply to several times of the rated pressure, which will result in damage to the pump or pipe rupture. This must be absolutely avoided when transporting hazardous media. Therefore, it is necessary to install safety devices such as pressure switches.

(3) If the GS sanitary stainless steel screw pump is suddenly powered off during operation, the power supply must be turned off immediately and the outlet valve must be closed.

(4) The universal joint of the pump bearing and transmission shaft is lubricated with lithium base grease. Food lubricating grease is used at the ball joint of the transmission shaft of the pump for conveying food medium.

(5) GS sanitary stainless steel screw pump

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us