PRODUCTS

1. Product introduction

The sanitary stainless steel pneumatic diaphragm pump produced by our company is the core product of cooperation technology with foreign enterprises, and is made in China with foreign technologies. The product design is reasonable, with the advantages of no sealing, explosion-proof, low shear, easy maintenance, idling allowed, portable, self priming, multi material selection, etc.

2. Product pictures

3. Scope of application

1. Beverage industry: fermented concentrate, dregs, hot fruit juice, syrup, gas-liquid mixture, corn syrup, wine, fruit juice, jam

2. Pharmaceutical industry: tablets, ointment, alcohol, filtering aids, plant extracts

3. Food industry: honey, essence, spices, chocolate, vinegar, syrup, vegetable oil, animal blood

4. Daily chemical industry: detergent, cream, hand sanitizer, surfactant, shampoo, latex, hair gel, soap

5. Paper industry: lotion, adhesive, pigment, resin, dispersant, printing ink, kaolin, hydrogen peroxide

6. Oil tank car industry: tank car cleaning equipment, tank loading and discharge of vehicle oil tank

7. Automobile manufacturing: emulsion oil, grinding lotion, oil, coolant, hydraulic oil, paint preparation, paint additives, decontamination tank, cutting oil, water and glycol mixing, painting

4. Product Features

1. No irrigation is required. Super high suction. Suction lift up to 7m

2. Good trafficability. Particles and mud with a diameter of less than 10mm can pass through easily.

3. As the diaphragm will be separated from the transmission medium and the transmission mechanical parts, the medium will never leak out; And the pump itself has no shaft seal, which greatly extends the service life; According to different media, the diaphragm can be divided into neoprene, fluororubber, nitrile rubber, polytetrafluorohexene, Teflon (F46), etc.

4. The medium overflow part of the pump body can be divided into cast iron, stainless steel, fluorine lining and aluminum alloy according to different user requirements.

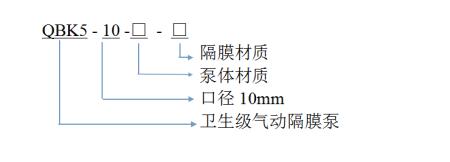

5. Model Meaning

6. Specifications

Note: 1. The materials of overcurrent components include 304 stainless steel and 316 stainless steel

2. Diaphragm materials include neoprene, fluororubber, NBR, PTFE, and Teflon (F46)

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) The equipment must be grounded during installation.

8. Precautions

(1) Before using the pump, each fastener of the pump should be checked.

(2) Before operating the equipment, you must read all instructions and understand the contents of various signs and labels.

(3) The conveyed medium and its temperature shall be within the allowable range of pump flow passage parts.

(4) When the conveying liquid is a medium that is easy to precipitate and crystallize, clean and discharge the deposits in the electric diaphragm pump in time after use to avoid damage when it is opened again.

(5) Do not exceed the maximum working pressure of the lowest rated component of the system being used.

9. Frequently Asked Questions

(1) If there are bubbles in the fluid, it may be that the suction pipe is loose and the diaphragm is broken.

(2) Fluid in exhaust gas may be caused by severe wear of vulnerable parts.

(3) Air leakage from the pump may be caused by wear of the central shaft seal.

10. Use needs

1. During the operation of the pump body, the maximum particle diameter contained in the internal medium shall not exceed the maximum safe passing particle diameter standard of the pump, otherwise it will cause blockage in the pump body.

2. During the operation of the pump, the air inlet pressure shall not exceed the maximum allowable working pressure of the pump, otherwise, excessive pressure will cause extreme compression of air. Once a failure occurs, it may affect the operation of the pump, and even cause dangerous situations, such as personal injury or property loss.

3. Clean the pipes inside the pump to ensure that the inside is clean and tidy, so that the pump can operate stably and normally.

4. The grounding inside the pump shall be carefully and carefully installed. Some wires with large cross section can be used for screw fixation and reliable grounding, so that the pump will not generate electrostatic sparks during operation and avoid some dangerous situations. Of course, the grounding should also be based on the actual situation, and there are also some special provisions in some special places. After the grounding installation is completed and the pump is used, it is also necessary to regularly check whether the grounding status is stable and reliable as it was at the beginning.

5. In addition, electrostatic sparks may also be generated if the connecting pipe head is loose and hit by transportation, so the diaphragm pump and all connecting pipe joints shall be fastened when the pump is installed. If conditions permit, anti-static hoses can be used.

6. It is better to install the pump in a well ventilated environment. Another point is to keep the pump away from some products that are too hot or flammable and explosive.

7. If the diaphragm pump is in the process of exhaust, be sure not to point the exhaust port at people, or impurities inside may cause harm to human body. In addition, if the pump conveys some flammable or toxic media, the pump should be transferred to some safe areas for medium discharge.

8. The high pressure of the fluid may cause serious casualties and property losses. Please do not carry out any maintenance work on the pump and material pipe system when the pump is pressurized. If maintenance is required, first cut off the air inlet of the pump, open the bypass pressure relief mechanism to depressurize the pipeline system, and slowly loosen the connected pipe joints.

9. Please do not send the pump directly to the manufacturer for repair if transporting harmful and toxic fluid. Properly handle according to local laws and regulations, and use permanent ball fittings to ensure service life.

10. Pump made of aluminum alloy is used for liquid delivery. Please do not use it to deliver liquid containing Fe3+, halogenated hydrocarbon and other substitute hydrocarbon solvents, which will cause corrosion and crack of pump body.

11. Ensure that all parts in contact with the conveying body will not be damaged by the conveyed fluid.

12. Ensure that all operators are familiar with the operation and use and master the precautions for safe use of the pump. If necessary, provide necessary protective equipment.

13. In places where the work is bad, such as construction sites, industrial and mining wastewater discharge, due to the impurities and complex composition in the sewage, the pipeline is easy to be blocked, so the electric pump will be overloaded, the motor will be vulnerable to heat, and the main shaft is easy to break.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us