PRODUCTS

1. Product introduction

Type D horizontal multistage centrifugal pump (horizontal multistage pump) is suitable for conveying clean water (impurity content less than 1%, particle size less than 0.1mm) and other liquids with physical and chemical properties similar to clean water.

The temperature of the medium conveyed by the DG type medium and low pressure boiler feed pump is not more than 105 ℃, which is suitable for small boiler feed water or conveying similar hot water.

The temperature of medium conveyed by DG type sub high pressure boiler feed pump is not more than 160 ℃, which is suitable for small boiler feed water or conveying similar hot water.

2. Product pictures

3. Scope of application

D. DG type horizontal multi-stage pump is applicable to industrial and urban water supply and drainage, pressurization water supply for high-rise buildings, garden sprinkler irrigation, fire pressurization, long-distance water supply, heating, bathroom and other cold and warm water cycle pressurization and equipment supporting, especially for small boiler water supply.

4. Product Features

1. Advanced hydraulic model, high efficiency and wide performance range.

2. The pump runs stably with low noise.

3. The shaft seal adopts soft packing seal or mechanical seal, which is safe and reliable, simple in structure, and convenient and quick in maintenance.

4. The shaft is fully sealed to ensure no contact with medium, no rust and long service life.

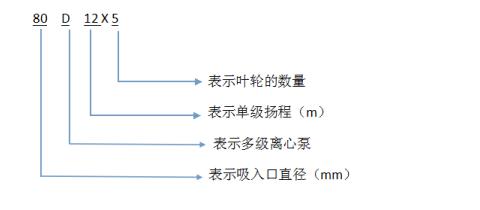

5. Model Meaning

6. Specifications

D. Technical parameters of DG type horizontal multistage pump:

Flow: 6.3-300m3/h;

Lift: 13-650m;

Power: 2.2-400KW;

Rotating speed: 1450-2950r/min;

Caliber: φ 50- φ 200;

Temperature range: ≤ 160 ℃;

Working pressure: ≤ 3.0Mpa.

7. Installation method

(1) The unit of horizontal multi-stage pump must have a concrete foundation with sufficient strength and size, and the quality of the foundation is about 3-5 times of the unit quality. The foundation of the pump is 50-70mm longer than the base of the pump, and anchor holes (3-4 times the diameter of steel pipes for anchor bolts) should be reserved.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall be equipped with corresponding supports.

(3) The specification and length of the pipeline used shall be suitable and have sufficient pressure bearing capacity to minimize the turning and accessories of the pipeline.

(4) Check whether the rotating parts of the pump are stuck or collided. If the pump is collided during transportation, check whether the coupling is concentric and adjust it.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) The horizontal multistage pump can only operate within the specified parameter range

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) The pump cannot be operated by closing the suction valve, otherwise the pump will run dry and the pump parts will be damaged.

(4) Observe the indication of pressure gauge and switch for adjustment during startup.

9. Frequently Asked Questions

(1) The water pump does not absorb water. It may be that the water injected into the pump is not enough,

(2) Insufficient flow of water pump may be due to blockage of water pump, excessive friction of sealing ring and insufficient rotation speed

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly check the pump performance (such as flow, lift, vibration, etc.) and make records. The maintenance items and the interval time between each maintenance depend on the working conditions and operating conditions of the pump.

(2) After the pump is started, do not close the discharge valve or close it for a long time, otherwise the liquid in the pump will overheat.

(3) When the pump stops, close the discharge valve of the pump to the minimum flow, but never close the suction valve of the pump.

(4) The medium conveyed by the pump shall not contain air or gas, otherwise, the flow and lift of the pump will not be measured accurately, and the parts will be damaged by grinding.

(5) The suction pipe of the pump shall be as short as possible, the pipe diameter shall be greater than or equal to the diameter of the suction inlet of the pump, and the bending radius of the suction pipe of the pump shall be as large as possible.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us