PRODUCTS

1. Product introduction

The QDLF (CDL) stainless steel vertical multistage pump produced by our company is a non self priming vertical multistage centrifugal pump designed and manufactured by absorbing the advanced technology at home and abroad. It uses standard vertical motor and quick assembly mechanical seal, which is very convenient for replacement. The overflow part of QDLF stainless steel multi-stage pump is made of stainless steel 304 material, which is suitable for slightly corrosive media. This product can replace the foreign CR, CRN and other similar products. After the product is put on the market, it is loved by the majority of users because of its high efficiency, energy saving, reliable quality, wide range of use and other characteristics.

2. Product pictures

3. Scope of application

(1) Water supply industry: water plant filtration and transmission, water plant partition water delivery, main pipe pressurization, high-rise building pressurization.

(2) Industrial pressurization system: process water system, cleaning system, high-pressure flushing system, fire protection system.

(3) Industrial liquid transportation: cooling and air conditioning system, boiler water supply and condensation system, machine tool matching, acid and alkali.

(4) Water treatment industry: ultrafiltration system, reverse osmosis system, distillation system, separator, swimming pool.

(5) Irrigation industry: farmland irrigation, sprinkler irrigation and drip irrigation.

(6) Chemical industry: thin, clean, non flammable and explosive liquid without solid particles or fibers.

4. Product Features

(1) QDLF (CDL) multi-stage pump is a vertical structure with small floor area. The center of gravity of the pump coincides with the center of the pump foot, so it runs stably, has small vibration and long service life.

(2) Long service life, beautiful appearance, especially high efficiency and energy saving

(3) After static balance verification, the impeller is fixed with the shaft sleeve and the shaft sleeve nuts on both sides. Its axial position can be adjusted through the shaft sleeve nuts. The axial force of the impeller is balanced by the symmetrical arrangement of its blades, and the residual axial force is borne by the bearing at the shaft end.

(4) The pump shaft is supported by two single row radial ball bearings or four radial thrust ball bearings. The bearings are installed in the bearing bodies at both ends of the pump body and lubricated with grease or thin oil.

(5) The water pump is directly driven by the motor through the elastic sleeve pin coupling.

(6) The shaft seal is a soft packing seal. In order to cool and lubricate the seal chamber and prevent air from entering the pump, a packing ring is installed between the packing. When the pump is working, a small amount of high-pressure water flows into the packing chamber through the trapezoidal groove on the open face of the pump cover or the external unsealed pipe parts, playing the role of water seal.

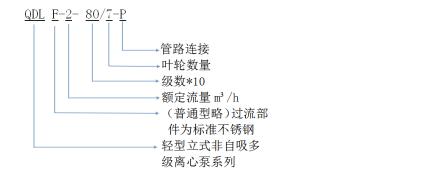

5. Model Meaning

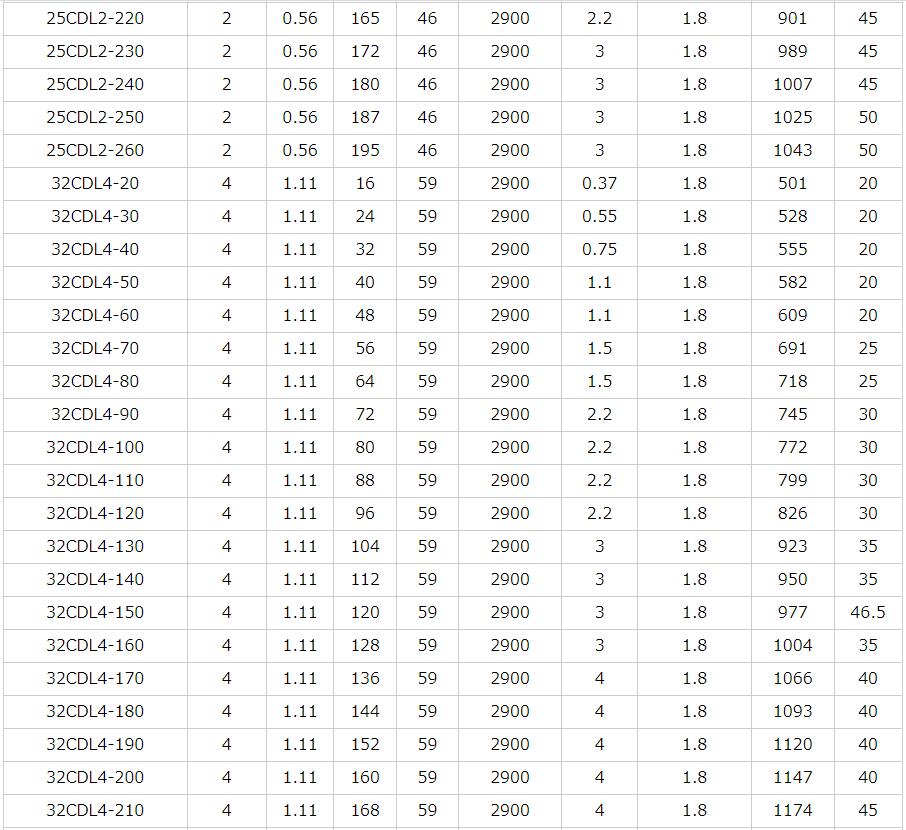

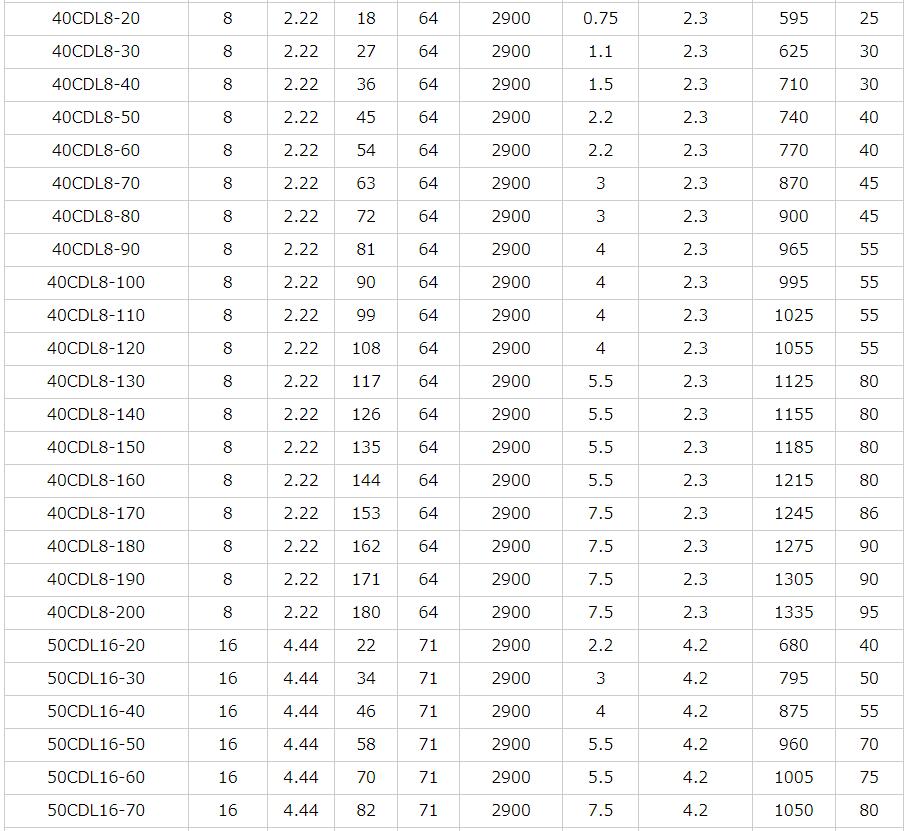

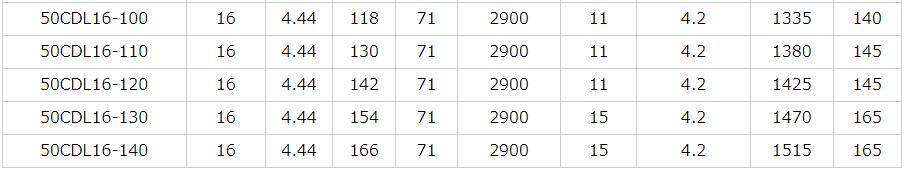

6. Specifications

7. Installation method

(1) Before the installation of stainless steel multi-stage pump, check whether the fasteners of the unit are loose, and whether the flow passage of the pump body is

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us