PRODUCTS

1. Product introduction

FSB type fluoroplastic alloy centrifugal pump (fluoroplastic chemical pump) is designed according to international standard size. The pump body is organically combined with metal and poly (perfluoroethylene propylene) (F46). The pump cover, impeller and shaft sleeve are all wrapped with metal inserts and molded by computer controlled sintering. The shaft seal is externally mounted corrugated pipe mechanical seal. The static ring is 99% alumina ceramic or silicon nitride. The dynamic ring is made of tetrafluoroethylene filling material, which is corrosion resistant and wear-resistant.

2. Product pictures

3. Scope of application

FSB fluoroplastic alloy centrifugal pump (fluoroplastic chemical pump) is widely used in petrochemical industry, acid and alkali production, non-ferrous metal smelting, automobile manufacturing pickling process, rare earth separation, pesticides, dyes, medicine, paper making, electroplating, radio and other industries, and is suitable for transporting clear liquid or corrosive media containing a small amount of particles (solid content ≤ 5%).

4. Product Features

FSB type fluoroplastic alloy centrifugal pump (fluoroplastic chemical pump) is composed of pump body, impeller, pump cover, seal, support, pump shaft, coupling, lifting bolt, nut, base plate, etc.

1. Pump body: one steel flange ring embedded in the left and right connection departments is molded into plastic alloy. It has the advantages of compact and reasonable structure, strong corrosion resistance, tight and reliable sealing function, stable operation, low noise, high mechanical strength, no aging, no toxin decomposition, convenient maintenance, smooth flow passage, high efficiency, energy conservation, etc.

2. A stainless steel (1Cr18Ni9Ti) pressed plastic alloy is embedded on the right side of the gland.

3. Impeller: the shaft connection method is adopted. The metal shaft is made of high-quality steel and then wrapped with fluoroplastic for high temperature compression molding, so that the impeller and the metal shaft are firmly integrated to ensure that the shaft root and the rear of the impeller bear the torque force when rotating, so that the flow passage part of the medium is plastic alloy.

4. Mechanical seal: WB2 type, ST type adjustable single end mechanical seal technology without cooling water is adopted, which is made of silicon carbide, high-purity alumina ceramics, filled with tetrafluoro, graphite and other materials.

5. Model Meaning

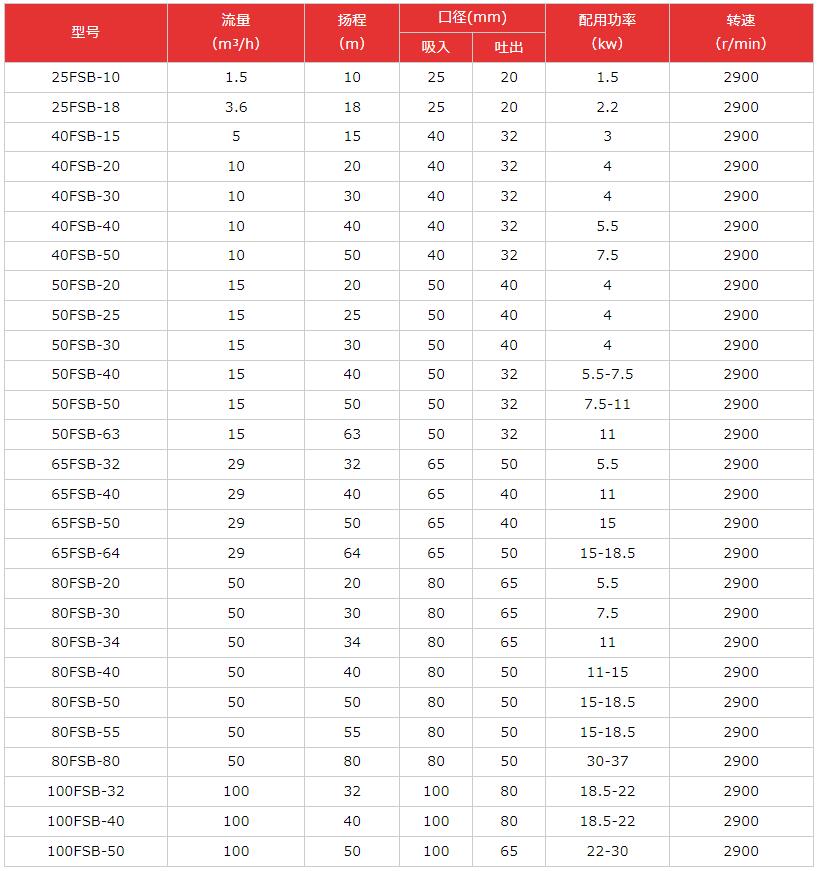

6. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Valves shall be installed on the inlet and outlet pipelines of the pump when the pump is installed under the condition of reverse flow, and it is better to install pipeline compensator. When the pump is under suction working condition, it is required to install valves at the inlet and outlet of the pump.

(4) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) It cannot be used when there is no liquid inside FSB fluoroplastic alloy centrifugal pump

(2) When the filling seal of FSB fluoroplastic alloy centrifugal pump is used and the filling box leaks, the leaking filler cannot be used again, and it can only be used after all of them are replaced.

(3) If FSB fluoroplastic alloy centrifugal pump uses mechanical seal, it is necessary to ensure that there is enough liquid inside for mechanical seal flushing.

9. Frequently Asked Questions

(1) If the water pump does not discharge water, it may be that there is air in the pump chamber.

(2) Insufficient pump flow may be caused by partial blockage of pipes and impeller of pump flow passage, insufficient valve opening, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Need to know

(1) The FSB fluoroplastic alloy centrifugal pump is prohibited from idling, and the minimum flow during pump operation is 35% of the design point.

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) The medium temperature change shall be controlled within 40 ℃. Excessive temperature rise/drop may cause damage to pump parts.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) The noise of the pump is ≤ 95dB. In case of vibration and noise, the pump should be shut down for inspection and troubleshooting before operation.

(6) Grease lubricated bearings shall be selected for the pump, and additional oil shall not be added to the bearing box.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us