PRODUCTS

1. Product introduction

FB stainless steel corrosion-resistant chemical pump is applicable to medium without solid particles, with medium temperature of O ℃~120 ℃ and inlet pressure of no more than 2kg/cm ²。 AFB stainless steel corrosion-resistant centrifugal pumps are improved and designed on the basis of F type corrosion-resistant pumps. They all use a new type of auxiliary impeller power shaft seal device, which is a single-stage single suction cantilever corrosion-resistant centrifugal pump.

2. Product pictures

3. Scope of application

FB stainless steel corrosion-resistant chemical pumps are widely used in chemical, petroleum, metallurgy, light industry, synthetic fiber, environmental protection, food, medicine and other departments. This kind of product has the advantages of stable and reliable performance, good sealing performance, beautiful appearance, convenient use and maintenance, etc. It plays a great role in improving product quality, reducing leakage, emission, dripping and pollution.

4. Product Features

It adopts advanced hydraulic model, novel structure and high-strength combined single and double end mechanical seal, which has the advantages of high efficiency, energy saving, compact structure, stable performance and reliable use.

5. Model Meaning

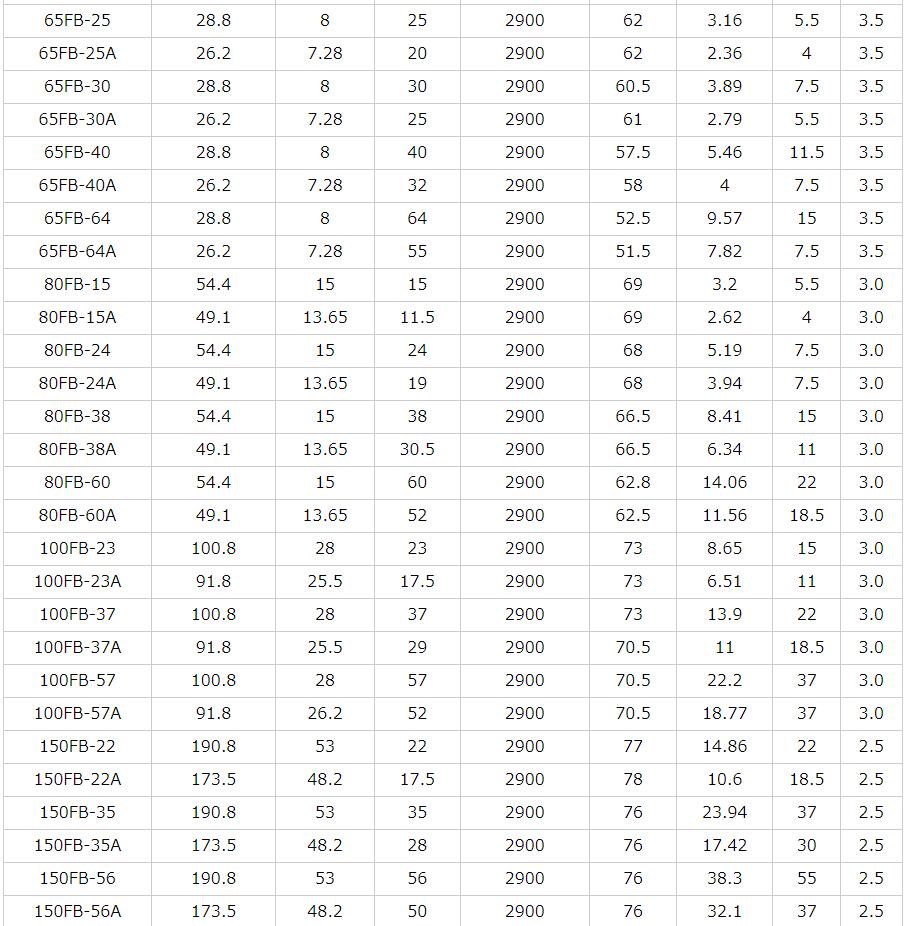

6. Specifications

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Valves shall be installed on the inlet and outlet pipelines of the pump when the pump is installed under the condition of reverse flow, and it is better to install pipeline compensator. When the pump is under suction working condition, it is required to install valves at the inlet and outlet of the pump.

(4) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) Before using the pump, each fastener of the pump should be checked.

(2) The rotation direction of the pump during operation shall conform to the requirements.

(3) The pump chamber can only be started when it is full of liquid. Do not dry burn and idle.

9. Frequently Asked Questions

(1) If the pump does not discharge water, check whether the pump reverses and whether the water inlet pipe leaks.

(2) Insufficient flow may cause the suction pipe diameter to be too small or the sealing ring to be severely worn.

(3) If the lift is too low, check whether the speed becomes slow or the flow is too large.

10. Need to know

(1) Starting:

a. Prepare necessary wrenches and tools

b. Check whether the lubricating grease in the oil cup of the sealing device is filled

c. Check whether the rotation direction of the pump is correct. Reverse rotation is strictly prohibited. Wrong rotation can loosen the impeller nut, which may lead to corrosion when the corrosive medium enters the shaft diameter, causing the pump to fail to work, and may also lead to an unfortunate accident when the impeller nut is thrown out. Before starting the pump, the coupling must be covered to ensure safe production.

d. After starting the motor, slowly open the gate valve at the outlet to make the pump work normally, and then open the valve to the required level

(2) Stop:

a. Close the gate valve of the pressure pipeline

b. Stop the motor

c. Close the gate valve of suction pipeline

d. Drain the liquid in the pump when the ambient temperature is lower than the freezing point of the liquid

e. If the pump is out of service for a long time, the corrosive medium in the pump shall be discharged and washed with clean water. After cleaning, it shall be kept properly

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us