PRODUCTS

1. Product introduction

IH stainless steel chemical pump (i.e. IH chemical pump) is a single-stage single suction cantilever centrifugal pump, designed according to the international standard ISO2858 and manufactured according to the international standard ISO5199/DIS. Compared with the old product, its technical indicators increase the efficiency by about 5% on average and reduce the NPSH by about 2m. It is an energy saving and efficient product with stable performance and standardized size of parts, It is a new energy-saving product determined by the Ministry of Machinery Industry to replace the old corrosion resistant pump and import., It has the characteristics of wide performance range, high efficiency, high level of "three modernizations" and convenient maintenance. Its efficiency is 5% higher than that of F type pump on average. It is an energy-saving product promoted by the country. It is used to transport liquids that do not contain solid particles, are corrosive and have viscosity similar to water.

2. Product pictures

3. Scope of application

The conveying medium temperature of IH stainless steel chemical pump (i.e. IH chemical pump) is - 20 ℃~105 ℃. If necessary, double end sealing cooling device is used, and the conveying medium temperature is below 300 ℃. IH stainless steel chemical pump is applicable to chemical, petroleum, metallurgy, electric power, paper making, food, pharmaceutical, environmental protection, wastewater treatment, synthetic fiber and other industries to transport various corrosive or non polluting media similar to water.

4. Product Features

1. High efficiency and energy saving: IH chemical pump is 5% more efficient than F type, which is an ideal energy-saving product;

2. Shaft seal: the shaft seal is a packing or mechanical seal, and the two types of seal pump covers can be used universally;

3. Suspension components: suspension components are designed in a universal way, with high universality and reliability.

4. Material: The main flow passage parts are made of stainless steel, which can meet the transportation of different media and have a long service life.

5. Fully sealed shaft: shaft sleeve, split cap, sealing gasket and "O" ring seal are used on the shaft to ensure that the shaft does not contact the medium and improve the service life of the shaft. Universal design is adopted with high degree of generalization.

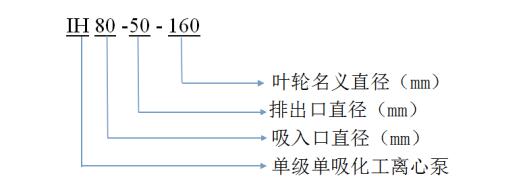

5. Model Meaning

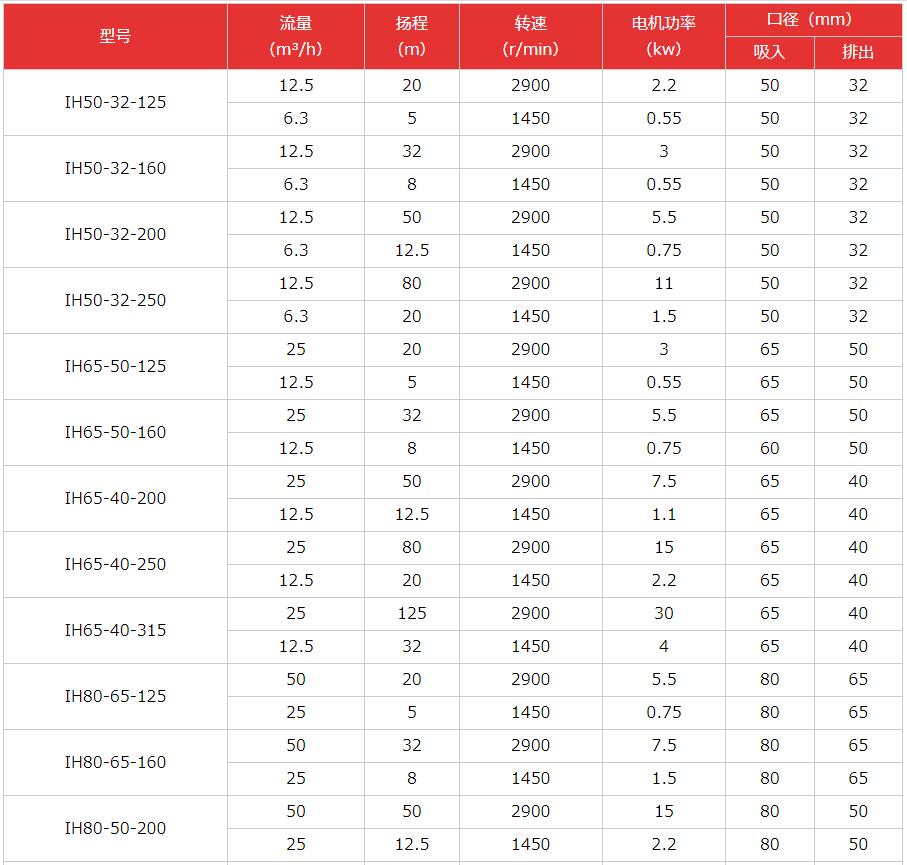

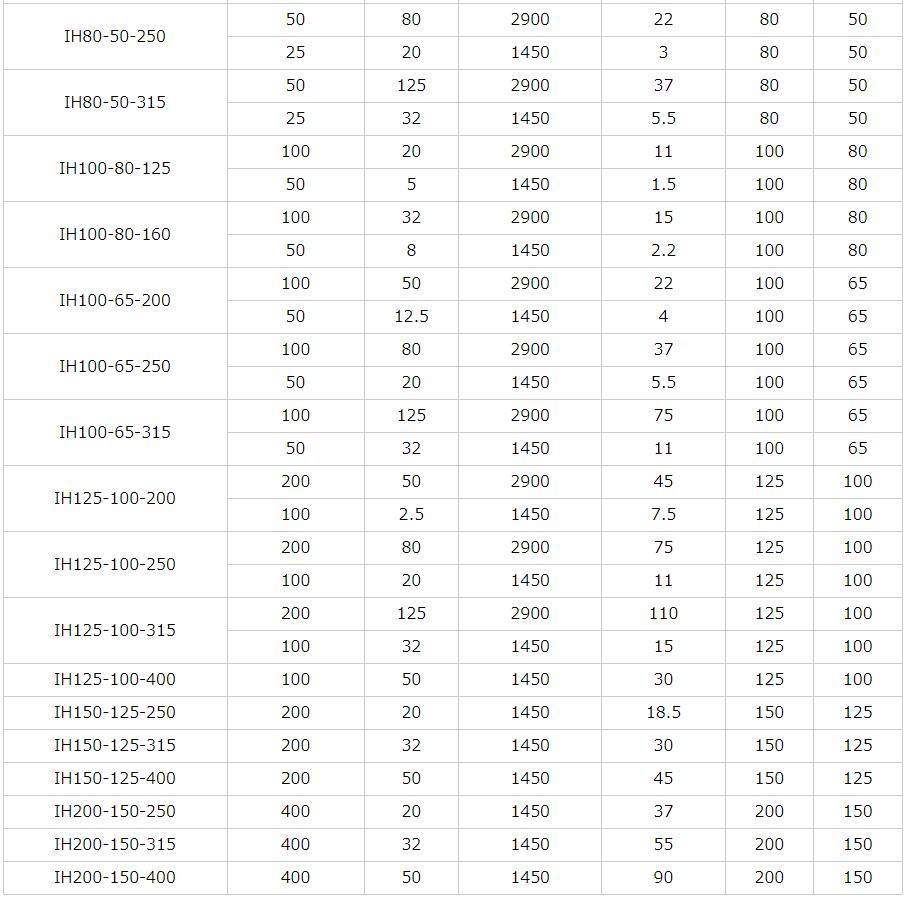

6. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Valves shall be installed on the inlet and outlet pipelines of the pump when the pump is installed under the condition of reverse flow, and it is better to install pipeline compensator. When the pump is under suction working condition, it is required to install valves at the inlet and outlet of the pump.

(4) Check whether the rotating parts of the pump are stuck or collided. If the pump is collided during transportation, check whether the coupling is concentric and adjust it.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) Before use, the pump shall be filled with enough liquid. It is strictly forbidden to start the pump when there is no liquid or insufficient liquid.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) The unit operates for 5-10 minutes. If there is no abnormal phenomenon, it can be put into operation.

(4) During shutdown, the outlet valve shall be closed first, and then the power supply shall be cut off.

9. Frequently Asked Questions

(1) If the water pump does not discharge water, it may be that there is air in the pump chamber.

(2) Insufficient pump flow may be caused by partial blockage of pipes and impeller of pump flow passage, insufficient valve opening, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly fill the bearing box with high-quality calcium base grease and replace the wearing parts

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) When the pump is shut down for a long time, the inner flow passage of the pump shall be cleaned.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) The noise of the pump is ≤ 95dB. In case of vibration and noise, the pump should be shut down for inspection and troubleshooting before operation.

(6) The pump shall be used under suction, and the pump shall be filled or vacuumized before starting; The pump is used under the condition of reverse filling. Before starting, the pump shall be filled with the infusion fluid. After the air in the pump is expelled, the gate valve of the discharge pipe shall be closed.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us