PRODUCTS

1. Product introduction

Some impellers of LQFZ direct coupled corrosion-resistant stainless steel self-priming pumps adopt semi open structure, while others adopt closed structure. In addition, the pump and motor are connected in two ways: direct coupled type and bracket type with bearings. All pump shaft seals adopt mechanical seals with the current advanced cantilever technology in West Germany. Stainless steel corrosion-resistant centrifugal pumps combine excellent structure, performance and shape, The components and connecting frame of the secondary flow passage are made of high-quality stainless steel. Therefore, the two series of products have a series of advantages, such as corrosion resistance, reliable performance, convenient use and maintenance, compact structure, low energy consumption, and good sealing performance.

2. Product pictures

3. Scope of application

LQFZ directly connected stainless steel corrosion resistant self-priming pump is used to transport liquids with corrosivity, hygiene requirements and low viscosity, and is widely used in food, beverage, medicine, cosmetics, sewage treatment, chemical (or fine chemical), electroplating and other industries.

4. Product Features

1. The centrifugal pump is made of corrosion-resistant and stainless steel materials. It not only has corrosion-resistant properties, but also has the characteristics of centrifugal pump. In terms of service life, it also has a long service life because of the use of stainless steel materials.

2. The pump also has self-priming function. It only needs to fill the liquid for the first time to exhaust the air, and then it can directly absorb the material.

3. The installation method of stainless steel self-priming corrosion resistant centrifugal pump is also very simple as long as the pipeline is not pressed above the pump.

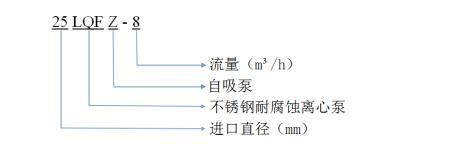

5. Model Meaning

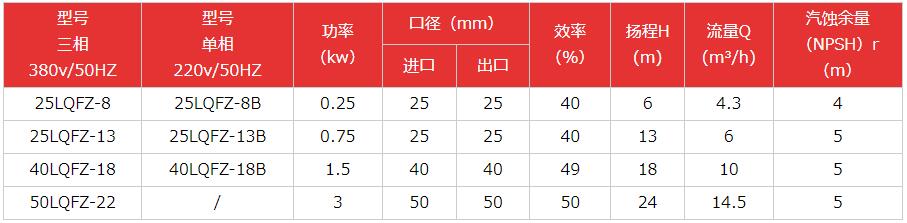

6. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

7. Installation method

(1) The stainless steel self-priming pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) The pump shall be installed as close to the material as possible (the shorter the inlet pipeline, the faster the self-priming time.)

(4) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) The stainless steel self-priming pump shall be filled with enough liquid before use. It is strictly forbidden to start the pump when there is no liquid or insufficient liquid.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) The unit operates for 5-10 minutes. If there is no abnormal phenomenon, it can be put into operation.

(4) During shutdown, the outlet valve shall be closed first, and then the power supply shall be cut off.

9. Frequently Asked Questions

(1) If the water pump does not discharge water, it may be that there is air in the pump chamber.

(2) Insufficient pump flow may be caused by partial blockage of pipes and impeller of pump flow passage, insufficient valve opening, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) The disassembly sequence is as follows: remove the motor, bracket, bottom plate screws, remove the mechanical seal cover, loosen the dynamic ring snap ring bolts, static ring pressure plate bolts, front and rear pump cover bolts, unscrew the vane screw of the impeller shaft pull rod, screw out 3~5mm, knock the pull rod with a hammer, and then remove the pull rod, impeller and mechanical seal after loosening the impeller. When removing the mechanical seal, it should be manually operated, and it should not be knocked with metal tools to prevent damage.

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) When the pump is shut down for a long time, the inner flow passage of the pump shall be cleaned.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) If the specific gravity of the conveying medium is greater than 1.2, an additional motor shall be provided, otherwise the lift will be affected or the motor will be burnt..

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us