PRODUCTS

1、 Product introduction:

LQZP petrochemical process is a horizontal, single-stage, single suction hanging hip centrifugal pump, designed according to API 610 specification of American Petroleum Institute, and characterized by high reliability, long service life, stable operation, high universality, good cavitation performance and high efficiency.

2、 Product picture:

3、 Performance range

Temperature: - 80~+450 ℃ Pressure:~50bar Flow: - 2600 m3/h Lift: - 300 m

4、 Scope of application

Conveying low or high temperature, neutral or corrosive, clean or containing solid particles, mainly used in:

◎ Refinery, petrochemical industry, coal chemical industry and low temperature range

◎ Water supply plant, seawater desalination plant and power plant

◎ Environmental protection project

◎ Chemical industry, paper making, pulp industry, sugar making

5、 Structural characteristics

LQZP petrochemical process, the main body adopts radial split structure, and the pump body is divided into angle supports. The pump body with a diameter of more than 80mm is designed as double volute, which can balance the radial force well. The pump body and the pump cover are connected to form a pressure shell, which is highly safe and reliable.

The pump body can be equipped with a high fruit temperature (cooling) jacket, and the pump cover is equipped with a cooling water chamber to insulate (cool) the pump working chamber and expand the use range of this series of pumps. The impeller can be either a closed mechanism or an open structure, which is also suitable for conveying different media. The impeller is equipped with a mouth ring and a balance hole to balance the axial force. It can also be equipped with inducer to improve the vapor turbidity performance of the pump.

The bearing box can be made of cast iron and steel. The bearing is lubricated with thin oil, and the box is equipped with a constant oil cup, which can automatically control the oil level. The rear end bearing can adopt angular contact ball bearing or tapered roller bearing according to the working pressure and inlet pressure. The bearing is equipped with three cooling modes: air cooling water cooling and air cooling, which are suitable for different working conditions.

The seal chamber is completely designed in accordance with API682 standard, and can be equipped with single section and double end mechanical seals. The corrugated pipe mechanical seal can also adopt various flushing schemes. From the drive end, the pump is timely.

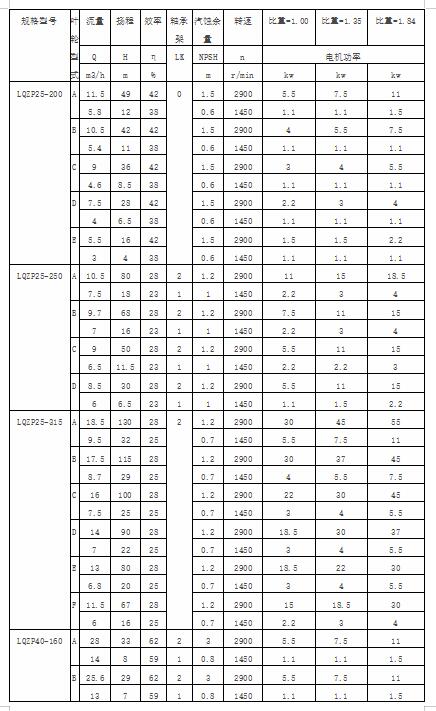

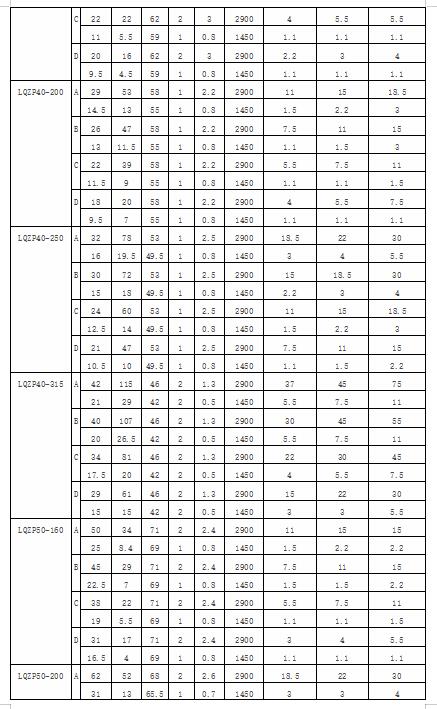

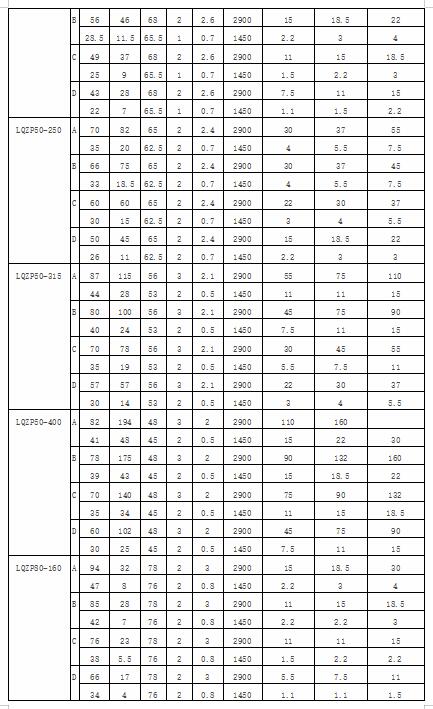

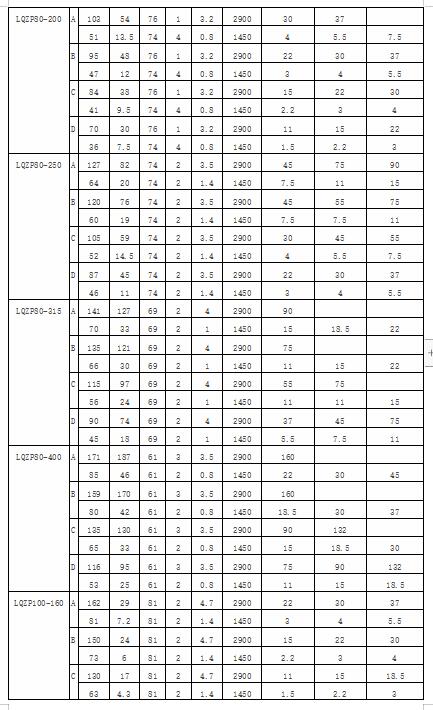

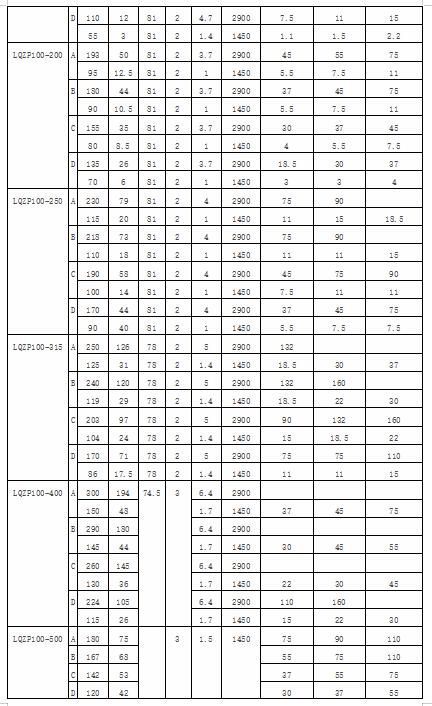

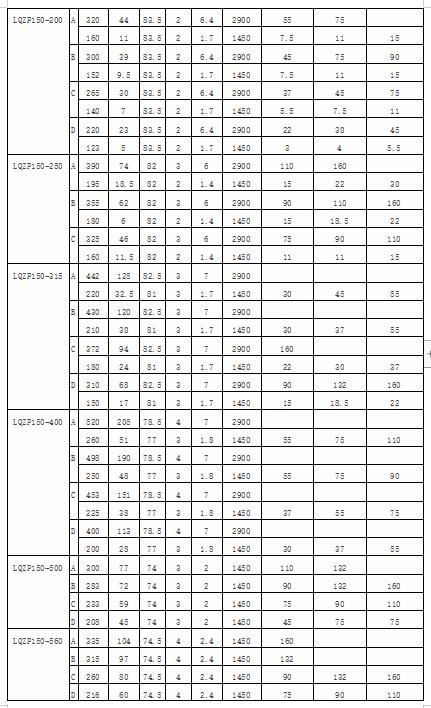

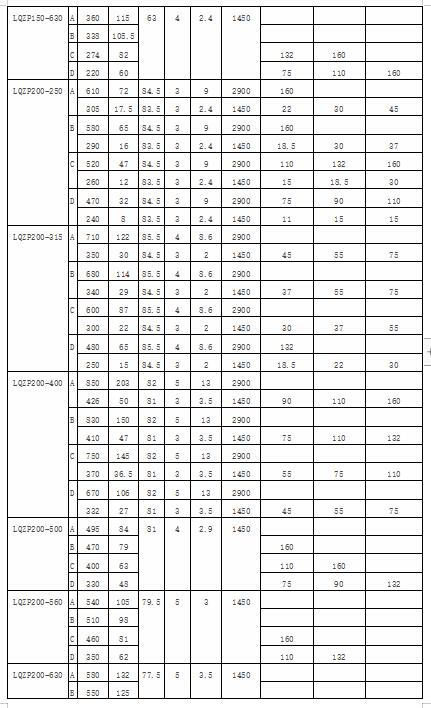

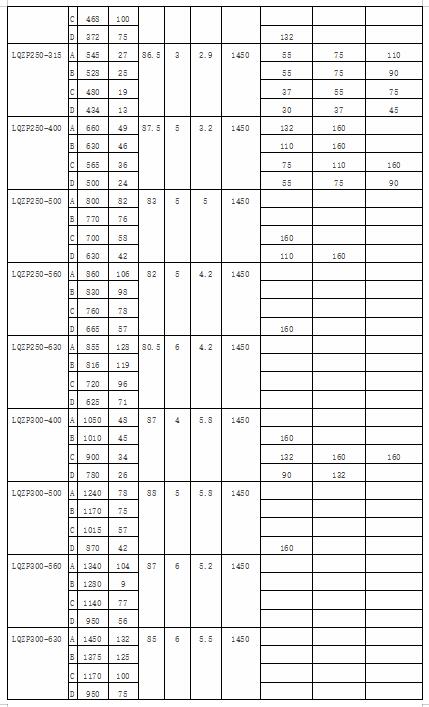

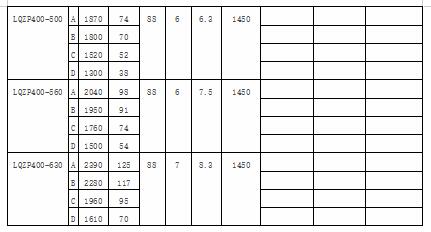

6、 Model selection parameters

7、 Need to know

(1) Regularly fill the bearing box with high-quality calcium base grease and replace the wearing parts

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) When the pump is shut down for a long time, the inner flow passage of the pump shall be cleaned.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) The noise of the pump is ≤ 95dB. In case of vibration and noise, the pump should be shut down for inspection and troubleshooting before operation.

(6) The pump shall be used under suction, and the pump shall be filled or vacuumized before starting; The pump is used under the condition of reverse filling. Before starting, the pump shall be filled with the infusion fluid. After the air in the pump is expelled, the gate valve of the discharge pipe shall be closed.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us