PRODUCTS

1. Product introduction

LQ3A stainless steel sanitary level cam rotor pump (sanitary food level rotor pump) is a multi-purpose two-way positive displacement pump manufactured by our company with advanced technology. The professional manufacturing technology and manufacturing accuracy of the products have reached the international advanced level.

This product uses two rotors that operate synchronously. The rotor is driven by a pair of synchronous gears in the box. Driven by the main and secondary shafts, the rotor rotates synchronously in the opposite direction to change the volume of the pump, thus forming a high vacuum degree and discharge pressure, which is particularly suitable for the transportation of sanitary grade media and corrosive high viscosity media.

The manufacturing standards of LQ3A stainless steel sanitary cam rotor pump are divided into sanitary and corrosion resistant series; In the structure, it is made of high pressure high viscosity and high pressure low viscosity. The sealing device of the core part of the product is made of different materials and sealing forms according to the different characteristics of different media, which improves the professional conveying performance of the product.

2. Product pictures

3. Scope of application

LQ3A stainless steel sanitary cam type double rotor pump is widely used in petrochemical, fine chemical, daily chemical, pharmaceutical, food, environmental protection, paper making, chemical fiber, coating, metallurgy, oil field and other industries.

4. Product Features

1. During the design and production process of LQ3A stainless steel sanitary rotor pump, there are requirements for internal parts and components, and all parts and components should be made of stainless steel materials. Of course, the stainless steel materials used should meet the sanitary standards of production, followed by the non-toxic rubber materials used for internal seals, so that the pump body has a good non-toxic sealing performance, and the whole pump can operate reliably.

2. LQ3A stainless steel sanitary rotor pump adopts streamline structure in the design of internal structure, which is mainly to prevent the pump from polluting the medium during medium delivery. Therefore, in addition to streamline structure, there should be no dead points and non-metallic parts in the rotor chamber inside the rotor pump.

The LQ3A stainless steel sanitary rotor pump will not react to the medium when delivering it, and will change the quality of the medium. In addition to this, the rotor pump is different from other pumps in the past. It can be used to transport some media that are easy to foam in the transport process. Of course, the rotor pump can also transport some media with high viscosity, high concentration and particles that cannot be transported by some pumps. Like some three-phase mixed media such as steam, liquid and solid, the rotor pump can also transport. In a word, the range of media transported by the rotor pump is very wide, which can transport media with viscosity up to 1000000CP and solid content up to 55%.

4. The LQ3A stainless steel sanitary rotor pump is different from some traditional pumps in the form of mechanical seal. The rotor pump uses an external mechanical seal, so the rotor pump has achieved strict protection in terms of leakage prevention. After using the pump, it can also be directly flushed with water, and has the characteristics of high pressure resistance and wear resistance.

5. LQ3A stainless steel sanitary rotor pump is especially suitable for some long-distance and high resistance transportation methods, because the overall volume of the rotor pump is small, the flow is large, and the head pressure is high.

6. LQ3A stainless steel sanitary rotor pump has a certain clearance between the internal impeller and the transmission gear, and a certain clearance is guaranteed between all parts in the pump cavity during design and production, so the rotors do not contact each other during operation, and do not emit noise and wear, so the operation is very stable and reliable, and the service life has also increased.

7. LQ3A stainless steel sanitary rotor pump is equipped with a frequency converter inside, so the flow can be adjusted freely during operation, and it can also be used as a general metering pump.

8. The internal structure of LQ3A stainless steel sanitary rotor pump is very compact during design and production, so the subsequent use and maintenance are very convenient and the operation cost is very low.

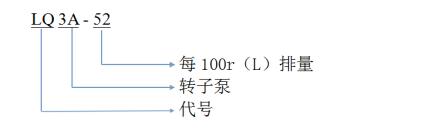

5. Model Meaning

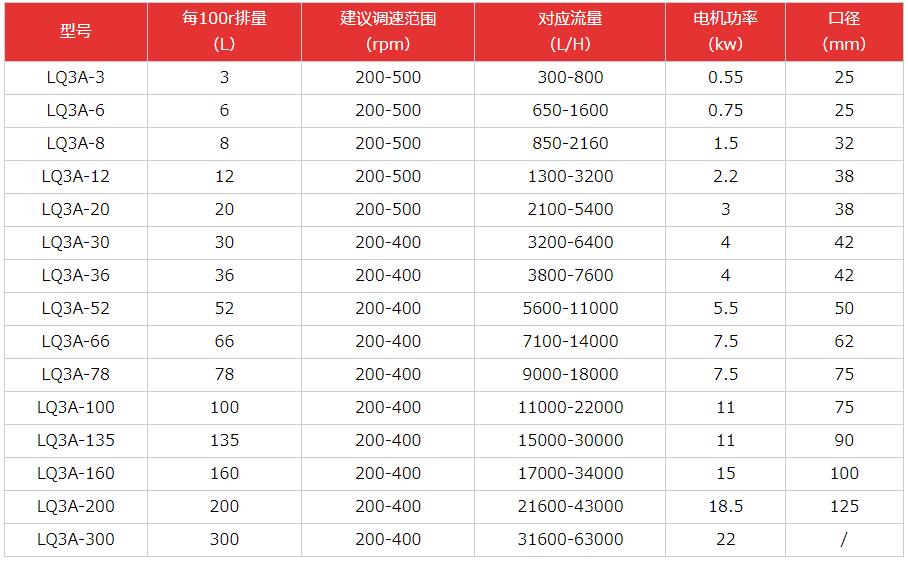

6. Specifications

Note: 1. If the parameters are different from those in the table during the model selection process, our factory can improve the model selection through technology.

2. Diversified caliber: quick clamp joint, national standard flange, threaded type.

3. Motor diversification: stepless speed regulating motor, gear reducer motor, variable frequency motor, etc.

4. Diversification of pump body: SS304/316/316L stainless steel and insulation jacket or upper in and lower out.

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Before the installation of a new pump, the container and pipeline system must be cleaned, and a filter must be installed before the pump inlet.

(4) Check whether the rotating parts of the pump are stuck or collided. If the pump is collided during transportation, check whether the coupling is concentric and adjust it.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

(6) After the pump is installed, please ground the motor at the grounding mark according to the national safety grounding regulations.

8. Precautions

(1) Before using LQ3A stainless steel sanitary cam type double rotors, sufficient liquid storage shall be added to the pump. It is strictly prohibited to start the pump when there is no liquid or insufficient liquid storage.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) To ensure that the pump body and motor are not damaged, please install a safety valve at the outlet of the pump and provide an over-current protection device.

(4) The valve of the inlet pipeline shall not be used to regulate the flow, so as to avoid the vibration of the pump caused by cavitation.

9. Frequently Asked Questions

(1) Insufficient flow may be caused by wear of pump chamber or rotor and blockage of outlet pipe.

(2) Motor heating may be caused by motor phase loss, high pressure or medium viscosity.

(3) Bearing heating may be caused by bent main shaft or insufficient oil in bearing oil chamber.

(4) The noise and vibration may be caused by unstable pipeline support, liquid mixed with gas, and excessive pump speed.

10. Use needs

(1) LQ3A stainless steel sanitary cam type double rotors regularly observe the oil level through the bearing box mirror, and supplement in time to prevent bearing wear.

(2) When working, the increase of viscosity, flow and pressure will easily cause overload of the motor, so check whether the pressure gauge, safety valve and overcurrent protection device are normal.

(3) The filter and filter screen shall be cleaned every month within one year after the installation of the new pump to avoid blockage, which may cause the pump to fail to work normally. It is strictly prohibited to use Y-type pipe filter, because the effective area of Y-type pipe filter is too small, which affects the medium flow rate.

(4) For the transportation of coagulable high viscosity medium, the medium in the pump shall be diluted before the pump is stopped to prevent the solidification of high viscosity medium in the pump. If necessary, the cleaning solution can be used to circulate (clean) the pump for several minutes

(5) In case of vibration and noise, the pump shall be shut down for inspection and troubleshooting before operation.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us