PRODUCTS

1. Product introduction

NYP high viscosity internal meshing rotor pump (high viscosity rotor pump) is a new type of displacement pump developed according to the needs of petroleum, chemical industry, paint, grease, medicine, dye, food and other industries. As the product can choose different materials and structures, NYP high viscosity pump is widely used for the transmission of media with different properties and viscosities.

Applicable medium temperature: - 10 ℃ - 200 ℃ (applicable temperature of NYPO. 78 and NYP2.3 is - 10 ℃ - 80 ℃).

Applicable medium viscosity: 1.0cSt - 300000cSt (applicable viscosity of NYPO. 78 and NYP2.3 is 1.0cSt - 10000cSt).

2. Product pictures

3. Scope of application

NYP rotor pump is especially suitable for conveying medium with high viscosity and consistency It is widely used in the transportation industry of various fluids, especially for fluid transportation with large viscosity change and wide range.

Plastic polyester industry: polyester resin, epoxy resin, hardener, isocyanate, moderator, polyol resin, surfactant, resin, polymer solvent, synthetic resin, binder, paste, plastic, polychlorinated triphenyl resin, acrylic resin, unsaturated polyester resin, alkyd resin, phenol resin, melamine resin, polyurethane, polystyrene, AS resin, ABS resin, epoxy resin, vinyl acetate, Artificial leather, polymer solvent.

Organic silicon industry: silica gel, silicone oil, glass adhesive base material, 107 adhesive.

Petrochemical and chemical industry: high viscosity fluid, asphalt, lubricating oil, grease, white latex, additive, petroleum, polymer, wax oil, rosin, fiber, viscose, glue, cleaner, resin, shampoo, silicone oil, chemical fluid

Paint and coating industry: dye, ink, solvent based paint, magnetic paint, paint, solvent, rubber solution, water-based paint, solvent paint, acrylic paint, water-based paint.

Daily chemical industry: fatty alcohol, detergent, shaving cream, shampoo, soap, face cream, essence, shampoo.

4. Product Features

(1) NYP rotor pump delivers liquid stably, without pulsation, with small vibration, low noise and strong self-priming performance.

(2) The utility model has the advantages of small size, light weight, long service life, etc.

(3) It can be equipped with a safety valve. When the pump or pipeline system is overpressure, the safety valve will open to form internal backflow to ensure system safety.

(4) The gear clearance can be adjusted according to the needs of viscosity without dismantling the pump to meet the process requirements of the pump under different viscosities.

(5) It is especially suitable for conveying medium with high viscosity and consistency.

5. Model Meaning

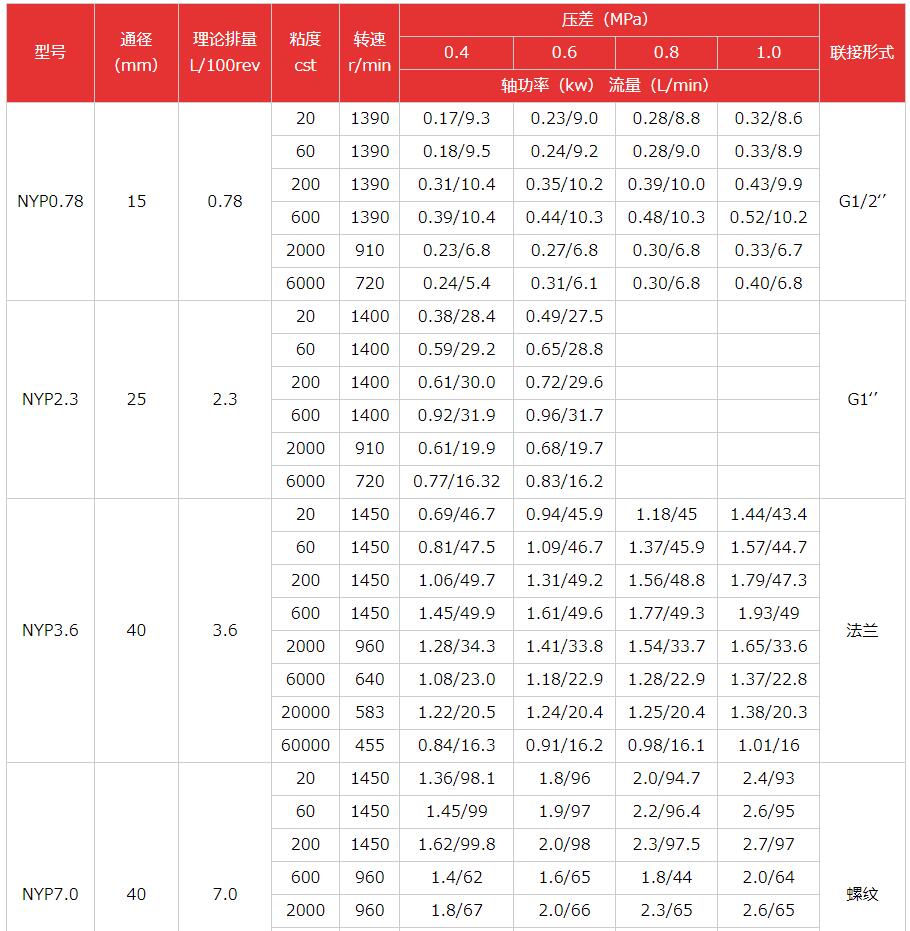

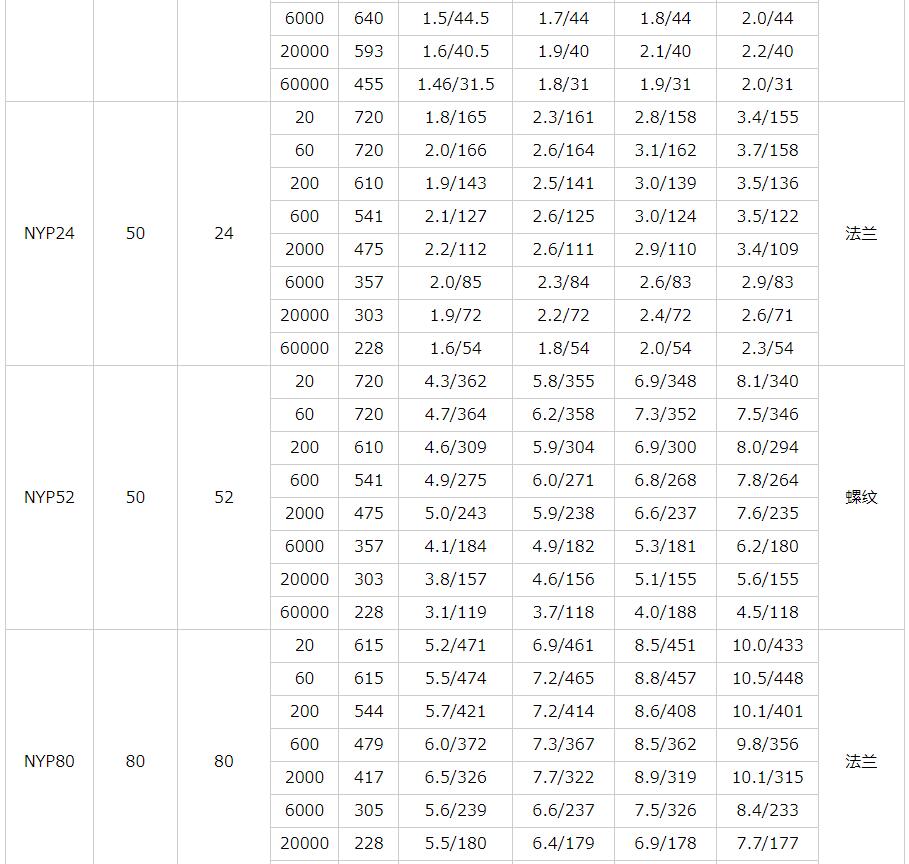

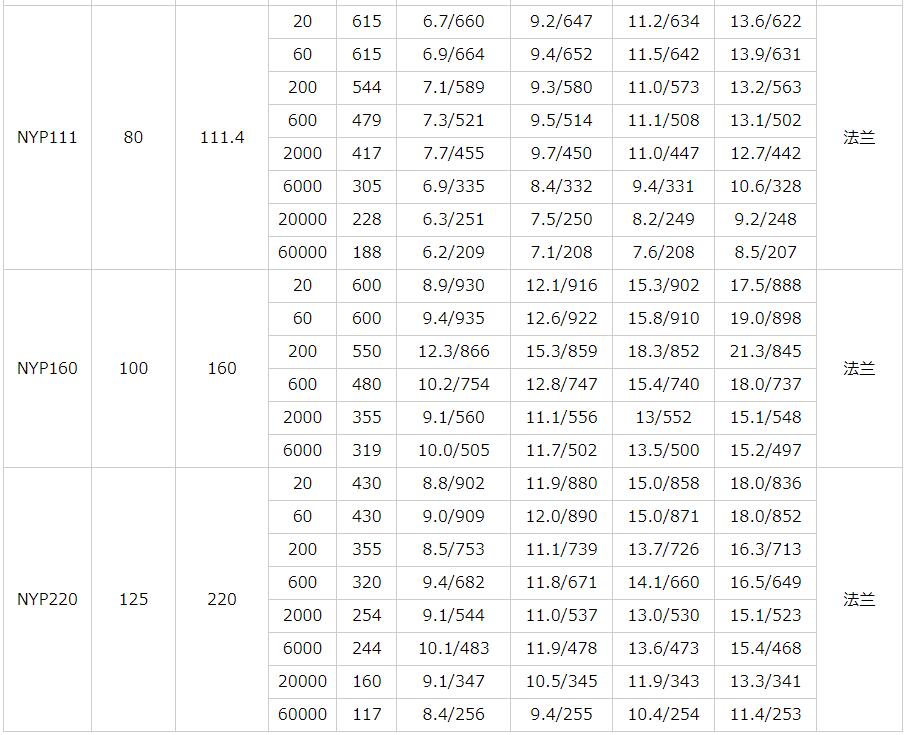

6. Specifications

7. Installation method

(1) The NYP rotor pump shall be installed and fixed on a stable foundation, and it is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Before the installation of a new pump, the container and pipeline system must be cleaned, and a filter must be installed before the pump inlet.

(4) Check whether the rotating parts of the pump are stuck or collided. If the pump is collided during transportation, check whether the coupling is concentric and adjust it.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

(6) After the pump is installed, please ground the motor at the grounding mark according to the national safety grounding regulations.

8. Precautions

(1) The NYP high viscosity internal meshing rotor pump shall not be started without liquid or insufficient liquid storage.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) When heating is needed: heat preservation can be carried out by passing hot steam, heat transfer oil and other heat mediums into the jacket cavity.

(4) When cooling is required: the constant temperature of the pump body can be maintained through various coolants

(2) The valve of the inlet pipeline shall not be used to regulate the flow, so as to avoid the vibration of the pump caused by cavitation.

9. Frequently Asked Questions

(1) Insufficient flow may be caused by wear of pump chamber or rotor and blockage of outlet pipe.

(2) Motor heating may be caused by motor phase loss, high pressure or medium viscosity.

(3) The noise and vibration may be caused by unstable pipeline support, liquid mixed with gas, and excessive pump speed.

10. Use needs

(2) The increase of viscosity, flow and pressure of NYP high viscosity internal meshing rotor pump is likely to cause overload of the motor when it is working. Check whether the pressure gauge, safety valve and overcurrent protection device are normal.

(3) The filter and filter screen shall be cleaned every month within one year after the installation of the new pump to avoid blockage, which may cause the pump to fail to work normally. It is strictly prohibited to use Y-type pipe filter, because the effective area of Y-type pipe filter is too small, which affects the medium flow rate.

(4) For the transportation of coagulable high viscosity medium, the medium in the pump shall be diluted before the pump is stopped to prevent the solidification of high viscosity medium in the pump. If necessary, the cleaning solution can be used to circulate (clean) the pump for several minutes

(5) In case of vibration and noise, the pump shall be shut down for inspection and troubleshooting before operation.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us