PRODUCTS

1. Product introduction

YPS double suction split pump (double suction pump, split pump) is a new product of the fourth generation of double suction pump developed by our company according to the market demand and on the basis of widely absorbing the advanced technology of similar products at home and abroad. Its remarkable features are perfect model spectrum, excellent model performance, novel and reliable structure, convenient maintenance and long service life. At present, our company produces 40 types of YPS pumps with 340 basic specifications. Through the use of prototype impeller, improved impeller and its cutting, the pump has a full and wide type spectrum and high efficiency. Within the range of the type spectrum, it can provide a pump that can properly meet the needs of users at any flow head working point.

After careful manufacturing and Wansheng's quality control, the products have reached the domestic leading level. Our company has obtained ISO09001 quality certification, and the product quality can be fully guaranteed. This series of pumps conform to ISO2548C and GB3216C standards.

2. Product pictures

3. Scope of application

YPS double suction split pump (double suction pump, split pump) is widely used in urban water supply and drainage and urban water supply; Water supply and drainage of central heating system; Water supply and drainage for iron and steel metallurgical enterprises, petroleum refineries, paper mills, oil fields, thermal power plants, airport construction, chemical fiber plants, textile plants, sugar plants, chemical plants and power stations; Water supply and drainage of fire fighting system and air conditioning system in factories and mines; Farmland drainage irrigation and various water conservancy projects.

4. Product Features

(1) The suction inlet and discharge outlet of YPS double suction split pump (double suction pump, split pump) are below the pump axis, perpendicular to the axis in a horizontal direction, and the pump casing is split in the middle. It is unnecessary to disassemble the water inlet and outlet pipelines and the motor (or other motor) during maintenance. Seen from the direction of the drive end to the pump, the water pump rotates clockwise. If necessary, it can also be produced in a counterclockwise direction. It should be specially proposed when ordering.

(2) The main parts of YPS double suction split pump (double suction pump, split pump) include: pump body, pump cover, impeller, shaft, double suction seal ring, shaft sleeve, bearing, etc.

(3) After static balance verification, the impeller is fixed with the shaft sleeve and the shaft sleeve nuts on both sides. Its axial position can be adjusted through the shaft sleeve nuts. The axial force of the impeller is balanced by the symmetrical arrangement of its blades, and the residual axial force is borne by the bearing at the shaft end.

(4) The pump shaft is supported by two single row radial ball bearings or four radial thrust ball bearings. The bearings are installed in the bearing bodies at both ends of the pump body and lubricated with grease or thin oil.

(5) The water pump is directly driven by the motor through the elastic sleeve pin coupling.

(6) The shaft seal is a soft packing seal. In order to cool and lubricate the seal chamber and prevent air from entering the pump, a packing ring is installed between the packing. When the pump is working, a small amount of high-pressure water flows into the packing chamber through the trapezoidal groove on the open face of the pump cover or the external unsealed pipe parts, playing the role of water seal.

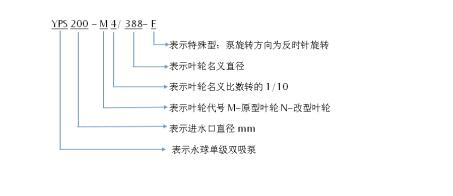

5. Model Meaning

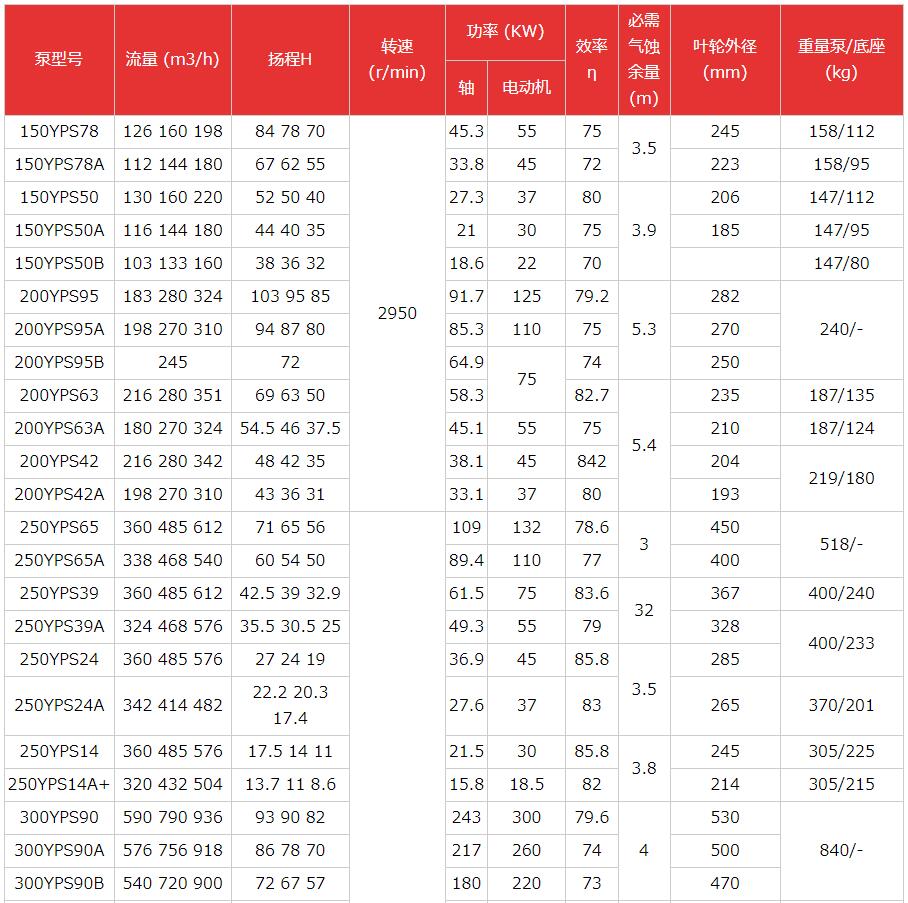

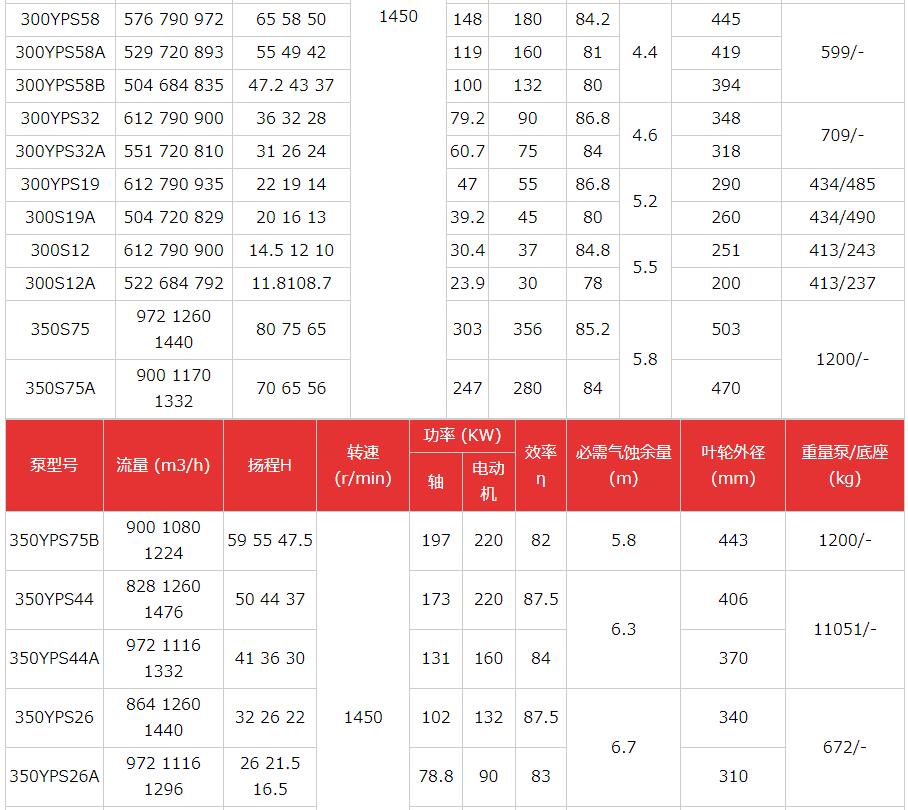

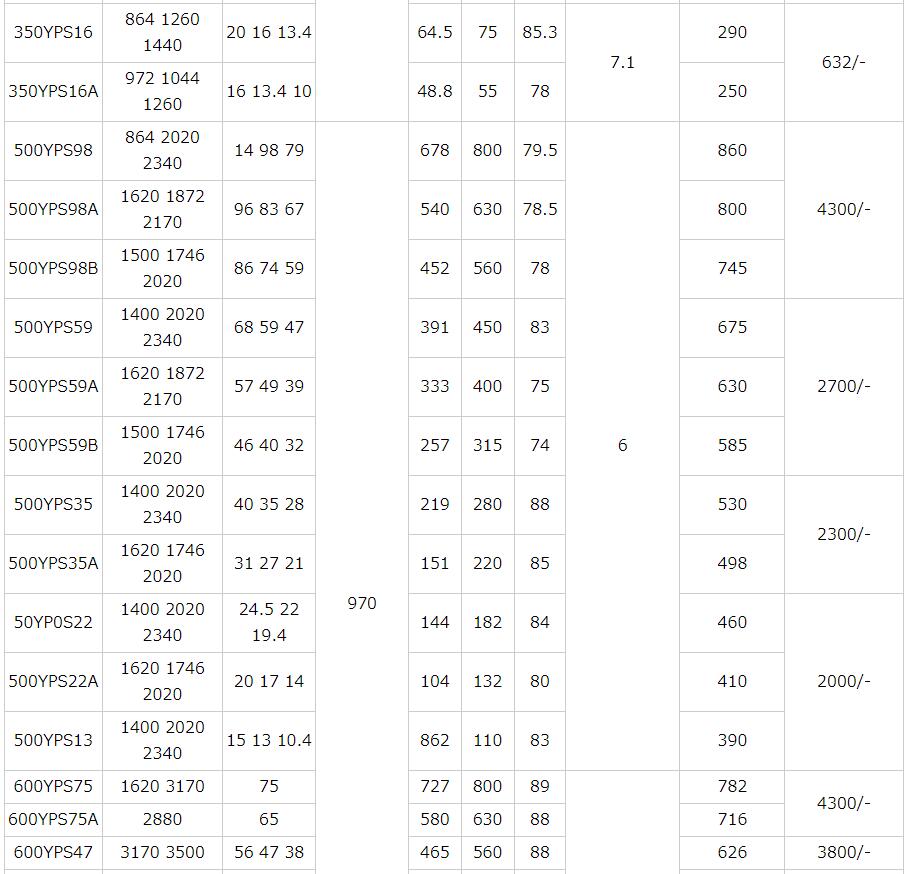

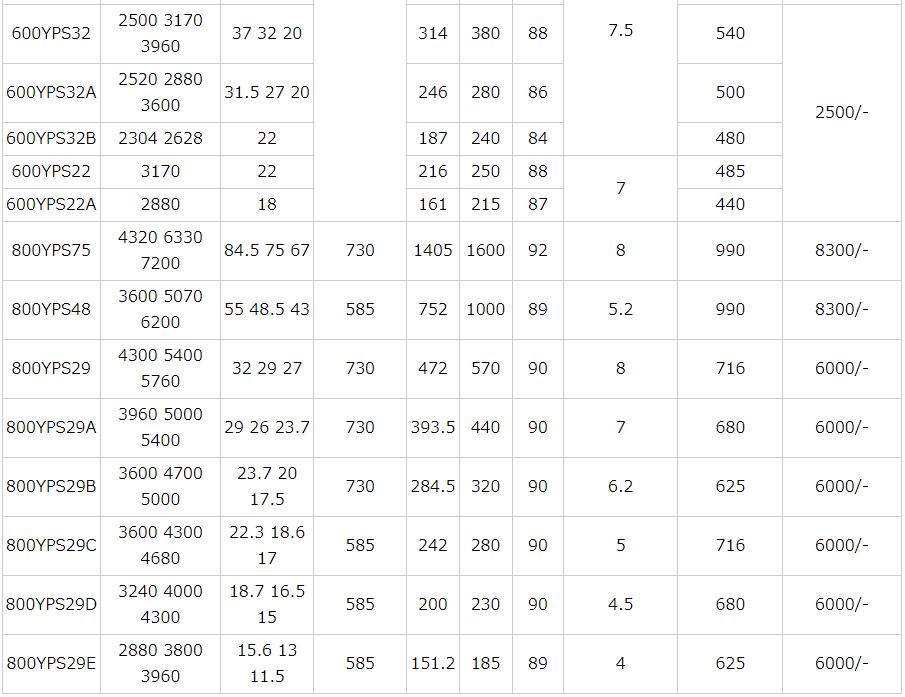

6. Performance parameters

Performance range

Flow: 38~3975m ³/ H

Lift: 6-200m

Rotating speed: 990r/min, 1480r/min and 2960r/min

Voltage: 380V, 6KV or 10KV

Inlet diameter: 150-600mm

Temperature range: maximum liquid temperature ≤ 80 ℃ (- 120 ℃). The ambient temperature is generally ≤ 40 ℃;

Maximum working pressure (inlet pressure+pumping pressure): 1.0MPa (Hsp ≤ 75m) or 1.6MPa (Hsp > 75m);

Special configuration can reach 1.6MPa or 2.5MPa respectively

7. Installation method

(1) Before installation, check whether the fasteners of the unit are loose and whether the flow passage of the pump body is blocked by foreign matters, so as to avoid damage to the impeller and pump body during the operation of the pump.

(2) During installation, the pipe weight shall not be added to the pump to avoid deformation of the pump.

(3) The foundation bolts must be tightened during installation to avoid the impact of vibration on pump performance during startup.

(4) For the convenience of maintenance and safety of use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, ensure the normal operation of the pump and increase the service life of the pump.

(5) The installation height of the pump, the length, diameter and flow rate of the pipeline shall comply with the calculation to minimize unnecessary losses.

8. Precautions

(1) When the pump is used for suction, it should be equipped with a bottom valve, and the inlet pipeline should not have too many bends, and there should be no water or air leakage.

(2) Regularly check the concentricity of the coupling

(3) The inlet pipe must be filled with liquid, and the pump is forbidden to operate for a long time under cavitation.

(4) If the pump is not used for a long time, it shall be disassembled, cleaned and oiled, and packed for storage.

9. Frequently Asked Questions

(1) The water pump does not absorb water, which may be caused by insufficient water injected into the pump; Air leaks from water pipes and instruments.

(2) The insufficient flow of the water pump may be caused by the blockage of the water pump, wear of the impeller, insufficient speed, etc.

(3) Excessive pump power may be used beyond the rated flow; The impeller is damaged.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly check the pump performance (such as flow, lift, vibration, etc.) and make records. The maintenance items and the interval time between each maintenance depend on the working conditions and operating conditions of the pump.

(2) After the pump has been running for a long time, if the noise and vibration of the unit increase due to mechanical wear, it shall be stopped for inspection, and the wearing parts shall be replaced if necessary,

(3) It is prohibited to run the motor for a long time with excessive current when the pump is running at large flow.

(4) The medium conveyed by the pump shall not contain air or gas, otherwise, the flow and lift of the pump will not be measured accurately, and the parts will be damaged by grinding.

(5) The suction pipe of the pump shall be as short as possible, the pipe diameter shall be greater than or equal to the diameter of the suction inlet of the pump, and the bending radius of the suction pipe of the pump shall be as large as possible.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us