PRODUCTS

1. Product introduction

IS horizontal single-stage single suction clean water centrifugal pump is an energy-saving pump jointly designed by the whole country. It is a renewal of BA, B and other single-stage clean water centrifugal pumps. Advantages: the layout of the whole series of hydraulic performance is reasonable, the user's selection range is wide, and the maintenance is convenient; The efficiency and suction head have reached the international average advanced level. This type of pump is applicable to industrial and urban water supply and drainage, as well as agricultural irrigation and drainage, and can be used to transport clean water or other liquids with physical and chemical properties similar to clean water. The temperature is not higher than 80 ℃.

2. Product pictures

3. Scope of application

(1) IS single-stage single suction centrifugal pump can transport clean water and liquids with physical properties similar to water. It is suitable for industrial and urban water supply and drainage, pressurized water supply for high-rise buildings, garden sprinkler irrigation, fire pressurization, long-distance transmission, HVAC refrigeration cycle, bathroom and other cold and warm water cycle pressurization and equipment supporting, with the operating temperature of T<80 ℃.

(2) ISR single-stage single suction centrifugal pump is suitable for pressurized circulating transmission of high-temperature hot water for boilers in metallurgy, chemical industry, textile, wood processing, paper making, hotels, bathrooms, hotels, etc., as well as circulating pumps for urban housing heating. The operating temperature is below 120 ℃.

(3) The IS type single-stage single suction centrifugal pump can also be used to transport petroleum products, gasoline, kerosene, diesel, etc. through special configuration by our company. The temperature of the conveyed medium is 120 ℃.

4. Product Features

1) The IS type horizontal single-stage single suction clean water centrifugal pump is designed according to the performance and size specified in the international standard ISO2858, and mainly consists of pump body, pump cover, impeller, shaft, seal ring, shaft sleeve and suspension bearing components.

(2) The pump body and pump cover of IS type horizontal single-stage single suction clean water centrifugal pump are divided from the back of the impeller, which is commonly referred to as the back door structure. It has the advantage of convenient maintenance. During maintenance, the pump body, suction pipeline, discharge pipeline and motor are not moved, and only the intermediate connecting piece of the extended coupling needs to be removed to exit the rotor part for maintenance.

(3) The casing of the pump (i.e. pump body and pump cover) constitutes the working chamber of the pump. The impeller, shaft and rolling bearing are the rotors of the pump. The suspension bearing components support the rotor part of the pump, and the rolling bearing receives the radial and axial forces of the pump.

(4) In order to balance the axial force of the pump, seal rings are set in front of and behind the impeller of most pumps, and balance holes are set on the rear cover plate of the impeller. Since the axial force of some pumps is not large, no seal rings and balance holes are set on the back of the impeller.

(5) The axial sealing ring of the pump is composed of the packing gland, packing ring and packing to prevent air intake or large amount of water leakage. If the impeller of the pump is balanced, the cavity with soft packing is connected to the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter air along the surface of the shaft sleeve. Therefore, a packing ring is installed in the packing chamber to lead the pressure water in the pump chamber to the packing ring through the small hole on the pump cover for sealing. If the impeller of the pump has no balance hole, since the liquid pressure at the back of the impeller is greater than the atmospheric pressure, there is no air leakage problem, so the packing ring can not be installed.

(6) In order to avoid shaft wear, a shaft sleeve is installed at the position where the shaft passes through the packing chamber. There should be an O-ring between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface.

(7) The drive mode of the pump is connected with the motor by lengthening the elastic coupling. The rotation direction of the pump is clockwise from the driving end.

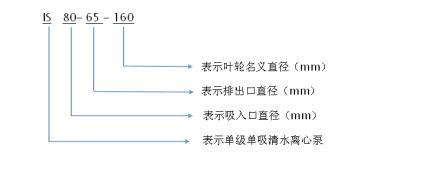

5. Model Meaning

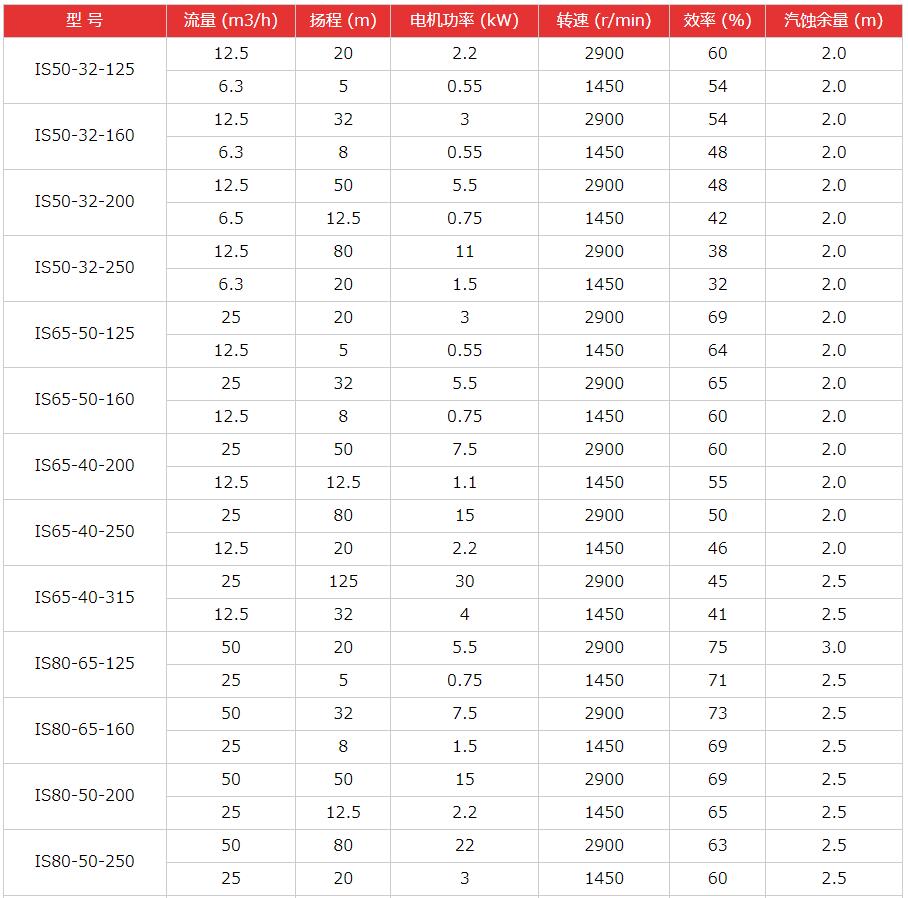

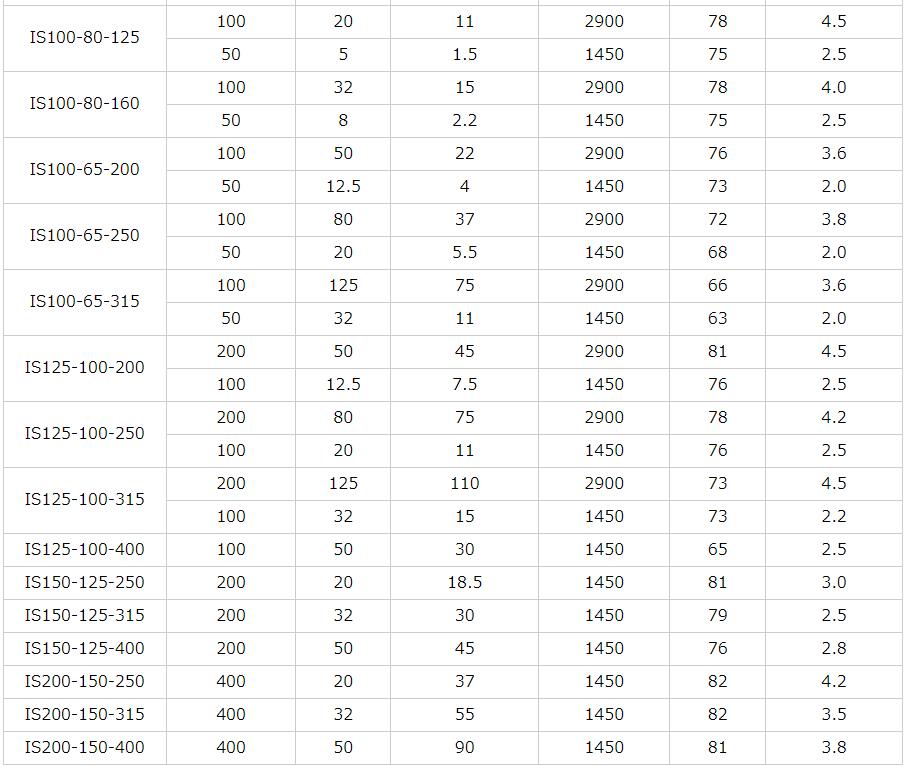

6. Specifications

7. Installation method

(1) Before installation, check whether the fasteners of the unit are loose and whether the flow passage of the pump body is blocked by foreign matters, so as to avoid damage to the impeller and pump body during the operation of the pump.

(2) During installation, the pipe weight shall not be added to the pump to avoid deformation of the pump.

(3) The foundation bolts must be tightened during installation to avoid the impact of vibration on pump performance during startup.

(4) For the convenience of maintenance and safety of use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, ensure the normal operation of the pump and increase the service life of the pump.

(5) The installation height of the pump, the length, diameter and flow rate of the pipeline shall comply with the calculation to minimize unnecessary losses.

8. Precautions

(1) When the pump is used for suction, it should be equipped with a bottom valve, and the inlet pipeline should not have too many bends, and there should be no water or air leakage.

(2) Test whether the rotation direction of the motor is correct. When looking from the motor end to the pump, it rotates clockwise. The test time should be short to avoid dry wear of the mechanical seal.

(3) The inlet pipe must be filled with liquid, and the pump is forbidden to operate for a long time under cavitation.

(4) If the pump is not used for a long time, it shall be disassembled, cleaned and oiled, and packed for storage.

9. Frequently Asked Questions

(1) The water pump does not absorb water, which may be due to insufficient water injected into the pump.

(2) The insufficient flow of the water pump may be caused by the blockage of the water pump, wear of the impeller, insufficient speed, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly check the pump performance (such as flow, lift, vibration, etc.) and make records. The maintenance items and the interval time between each maintenance depend on the working conditions and operating conditions of the pump.

(2) After the pump has been running for a long time, if the noise and vibration of the unit increase due to mechanical wear, it shall be stopped for inspection, and the wearing parts shall be replaced if necessary,

(3) It is prohibited to run the motor for a long time with excessive current when the pump is running at large flow.

(4) The medium conveyed by the pump shall not contain air or gas, otherwise, the flow and lift of the pump will not be measured accurately, and the parts will be damaged by grinding.

(5) The suction pipe of the pump shall be as short as possible, the pipe diameter shall be greater than or equal to the diameter of the suction inlet of the pump, and the bending radius of the suction pipe of the pump shall be as large as possible.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us