PRODUCTS

1. Product introduction

CZ series standard petrochemical process pumps (i.e. CZ chemical pump, petrochemical pump) are horizontal, single-stage, single suction centrifugal pumps; Its size and performance comply with DIN24256/ISO2858 standard. The performance range of CZ series standard chemical pump covers all the performances of IH series standard chemical pump, and its efficiency, cavitation performance and other indicators are superior to IH type pump.

2. Product pictures

3. Scope of application

CZ series standard petrochemical process pumps (i.e. CZ chemical pumps, petrochemical pumps) can transport low or high temperature liquids; Neutral or corrosive liquid; Clean or liquid containing solid particles. Particularly suitable for: chemical and petrochemical industries; Refinery; Paper mills and pulp industry; Grain production industry.

CZ series standard petrochemical process pumps (viz. CZ chemical pumps and petrochemical pumps) mainly transport inorganic and organic acids such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations.

2. Alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations.

3. Various salt solutions.

4. Various liquid petrochemical products and organic compounds,

5. Other corrosive raw materials and products.

6. At present, the corrosion resistant materials of our company can meet the requirements of the above media.

Performance range: flow: 3.2-2000m3/h; lift: 7-160m; working pressure: 2.5MPa; working temperature: - 80-300 ℃

Note: When ordering, please provide the details of the media to be transported.

4. Product Features

The pressure acting on the shaft seal is balanced by the balance hole on the auxiliary blade or impeller. The shaft seal can be either a soft packing seal (which can be cooled or not) or a single or double end non-equilibrium mechanical seal of various structures. The ball bearing is durable and the shaft diameter is sufficient to ensure smooth operation. The pump body of some specifications is designed as a double screw shell to balance the radial force. The bearing frame, including shaft, impeller, stuffing box, etc., forms a combined part, so that the pump body does not need to be removed from the pipe during maintenance (if the extended coupling is used, the motor does not need to be removed). The flange design adopts PN16 and PN25 (according to the difference of materials).

5. Use needs

(1) Regularly fill the bearing box with high-quality calcium base grease and replace the wearing parts

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) When the pump is shut down for a long time, the inner flow passage of the pump shall be cleaned.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) The noise of the pump is ≤ 95dB. In case of vibration and noise, the pump should be shut down for inspection and troubleshooting before operation.

(6) The pump shall be used under suction, and the pump shall be filled or vacuumized before starting; The pump is used under the condition of reverse filling. Before starting, the pump shall be filled with the infusion fluid. After the air in the pump is expelled, the gate valve of the discharge pipe shall be closed.

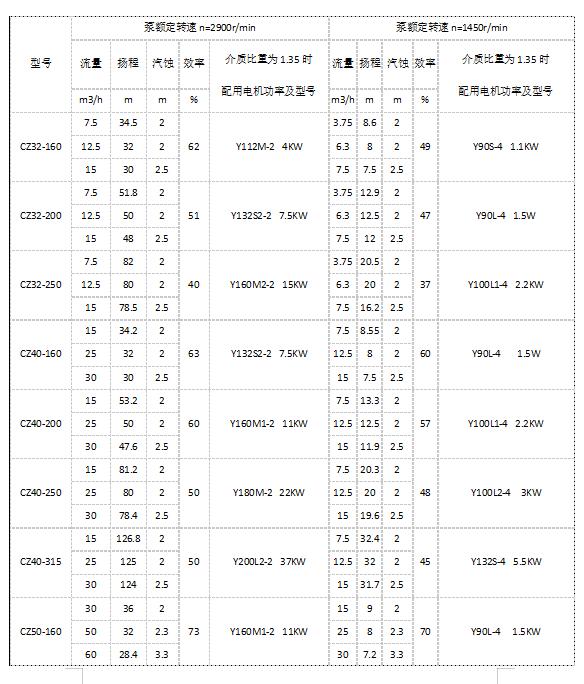

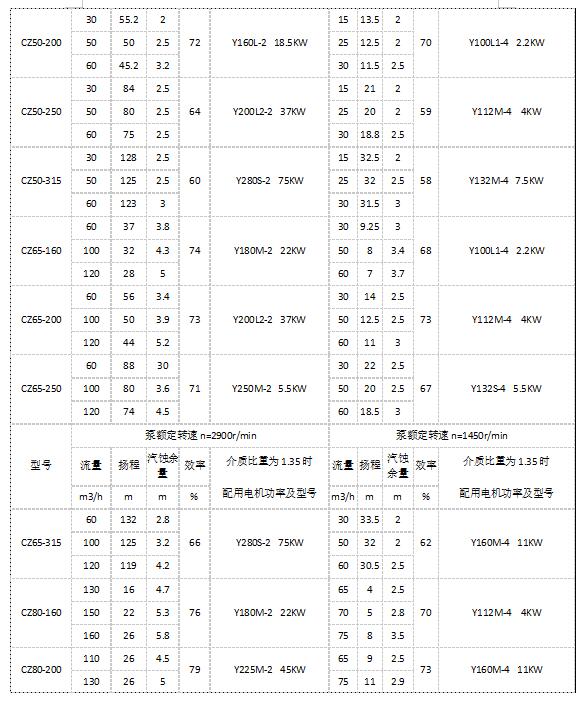

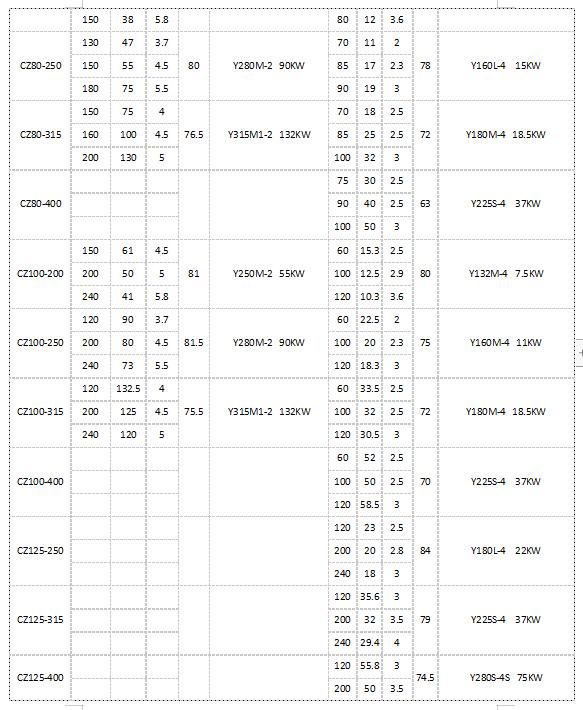

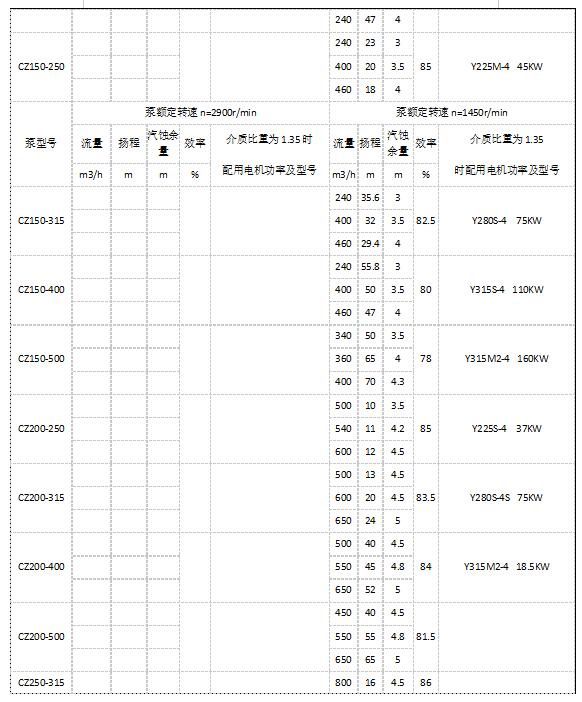

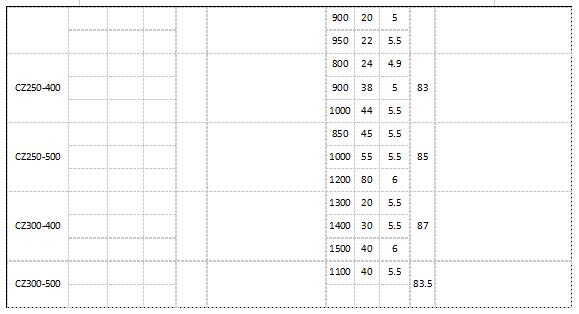

6. Detailed Performance Parameters of CZ Standard Chemical Pump

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us