PRODUCTS

1. Product introduction

IHF fluoroplastic alloy chemical centrifugal pump (abbreviated as fluoroplastic chemical pump and fluoroplastic lined centrifugal pump) is designed and manufactured according to international standards and combined with the process of non-metallic pump. The pump body is made of metal shell lined with perfluoroethylene propylene (F46). The pump cover, impeller and shaft sleeve are made of metal inserts wrapped with fluoroplastics by overall sintering and pressing. The shaft seal is made of externally mounted advanced corrugated pipe mechanical seal. The static ring is made of 99.9% aluminum oxide ceramics (or silicon nitride), and the dynamic ring is made of tetrafluoroethylene filling material, which has excellent corrosion resistance, wear resistance and sealing performance. The inlet and outlet of the pump are reinforced with cast steel body to enhance the pressure resistance of the pump. The actual use shows that the pump has the advantages of corrosion resistance, wear resistance, high temperature resistance, non aging, high mechanical strength, stable operation, advanced and reasonable structure, strict and reliable sealing performance, convenient disassembly and maintenance, and long service life.

2. Product pictures

3. Scope of application

IHF single-stage single suction fluorine plastic alloy chemical centrifugal pump (hereinafter referred to as IHF fluorine plastic chemical pump, fluorine lined centrifugal pump) is widely used in liquid transportation, wastewater treatment, acid addition and other processes in chemical, pharmaceutical, petroleum, metallurgy, electric power, electroplating, pickling, pesticide, paper making and other industries. This pump can transport any concentration of sulfuric acid, hydrochloric acid, nitric acid, acetic acid, hydrofluoric acid, aqua regia, strong alkali, strong oxidant, organic solvent and other strong corrosive media. It is one of the most advanced corrosion resistant equipment at present.

4. Product Features

This series of products are designed and manufactured according to international standards (ISO2858). The pump body is made of metal shell lined with fluoroplastics, and the impeller and pump cover are molded with metal inserts wrapped with fluoroplastics alloy, so that they have super impact resistance and excellent corrosion resistance. The shaft seal is an advanced external bellows mechanical seal. The sealing surfaces of the grinding machine are silicon carbide, ceramics, tetrafluoro and hard alloy. With a high performance price ratio, it is the most widely used anti-corrosion centrifugal pump in the chemical industry.

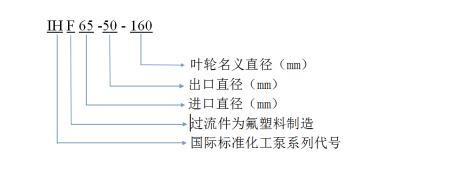

5. Model Meaning

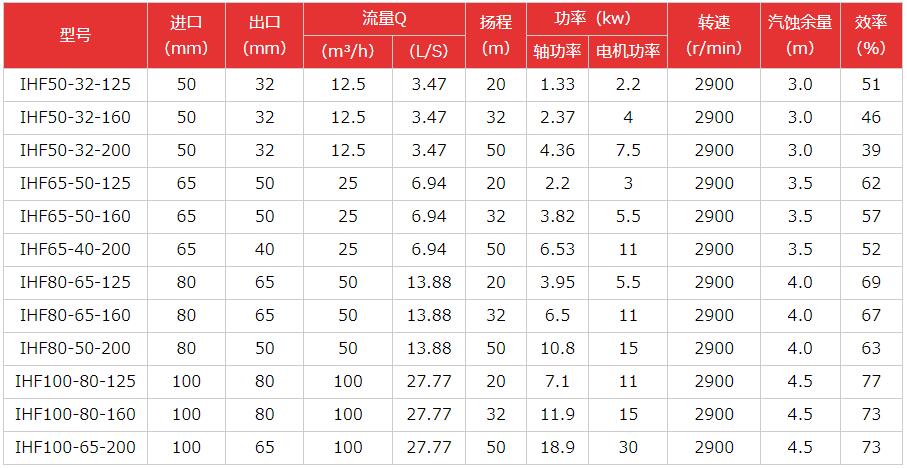

6. Specifications

7. Installation method

(1) The pump shall be installed and fixed on a stable foundation. It is better to lay a cushion between the base and the foundation. Ensure that the pump will not affect the vibration of the pipeline when it is started. The pump is not affected by other mechanical vibration.

(2) When installing the pipeline, it shall be noted that the inlet and outlet pipelines of the pump shall not exert force on the pump and shall be equipped with corresponding supports.

(3) Valves shall be installed on the inlet and outlet pipelines of the pump when the pump is installed under the condition of reverse flow, and it is better to install pipeline compensator. When the pump is under suction working condition, it is required to install valves at the inlet and outlet of the pump.

(4) Check whether the rotating parts of the pump are stuck or collided. If the pump is collided during transportation, check whether the coupling is concentric and adjust it.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) Before use, the pump shall be filled with enough liquid. It is strictly forbidden to start the pump when there is no liquid or insufficient liquid.

(2) Turn on the power supply, click the start switch first to see whether the running direction of the motor is consistent with the rotation direction of the pump. If not, correct it immediately, and do not reverse it.

(3) The unit operates for 5-10 minutes. If there is no abnormal phenomenon, it can be put into operation.

(4) During shutdown, the outlet valve shall be closed first, and then the power supply shall be cut off.

9. Frequently Asked Questions

(1) If the water pump does not discharge water, it may be that there is air in the pump chamber.

(2) Insufficient pump flow may be caused by partial blockage of pipes and impeller of pump flow passage, insufficient valve opening, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly fill the bearing box with high-quality calcium base grease and replace the wearing parts

(2) If cavitation occurs when the pump is running, it must be stopped within 1 minute.

(3) When the pump is shut down for a long time, the inner flow passage of the pump shall be cleaned.

(4) If the power is cut off suddenly when the pump is running, the power must be turned off immediately and the outlet valve must be closed.

(5) The noise of the pump is ≤ 95dB. In case of vibration and noise, the pump should be shut down for inspection and troubleshooting before operation.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us