PRODUCTS

1. Product overview

The company through the continuous introduction of advanced technology, vigorously promote scientific and technological innovation. The current submersible mixer QJB multi-functional spiral stagnant water mixer can be divided into high-speed mixing series and low-speed pushing series. High-speed mixing series QJB multi-functional rotary mixer is suitable for sewage treatment plant balance tank, nitrification/denitrification tank, sludge treatment and storage tank, as well as industrial processes to stir liquids containing suspended matter and solid debris to prevent precipitation. Low speed push-flow series QJB multi-functional rotary mixer is suitable for industrial and urban sewage treatment plants aeration tank and anaerobic tank, large nitrification and denitrification tank, disk activated sludge treatment tank, disinfection truck and industrial mixing. It produces a low tangential open strong water flow, which can easily create water flow in large volumes of fluids during the water cycle and the nitrification, nitrogen and phosphorus removal stages.

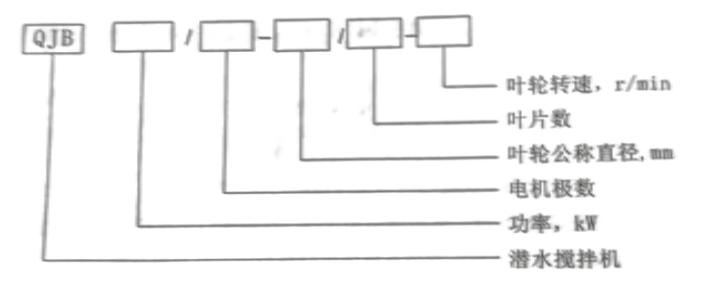

2、Type description

3.Use and scope of application

QJB multi-submersible mixer is suitable for treating urban sewage and industrial wastewater in environmental engineering

Sewage, waste water, sludge water mixing, uniform

Thickening process

Sludge dewatering process

Heat transfer optimization

Sump cleaning

Prevent particles from coagulating and settling on the pool wall and bottom

Remove suspended solids

Prevent icing

Create water flow

Full ring water, etc

It should be able to operate normally and continuously under the following conditions

1) The maximum medium temperature does not exceed 40℃:

2) The PH value of the medium is between 5-9:

3) The liquid density does not exceed 1.15 kg/m3;

4) Long-term diving operation, diving depth is generally not more than 20m.

! The submersible mixer must be completely submerged in water and cannot work in flammable, explosive and corrosive environments

4, product characteristics

1, QJB type submersible mixer compact structure, small size, light weight, simple operation and maintenance, easy installation and maintenance, long service life.

2, the impeller has the best hydraulic design structure, high working efficiency, swept back blade with self-cleaning function to prevent impurities

Objects are entangled and blocked.

3, mixed with the aeration system can greatly reduce energy consumption, significantly improve oxygen uptake, and effectively prevent precipitation.

4, the motor winding insulation level is F, the protection level is IP68, the selection of imported one-time lubrication maintenance-free quality

Bearings, with oil chamber leak detection and a unique patented motor winding overheat protection and anti-condensation device, make the motor work

Make it safer and more reliable.

5, two independent mechanical seal, mechanical seal friction material for corrosion resistant tungsten carbide. All exposed tight

Firmware is made of stainless steel.

6. Unique cable seal design eliminates the hidden danger of cable leakage.

7, standard parts using point separation technology, can effectively prevent corrosion.

5. Host structure

QJB type multi-functional spiral submersible mixer is mainly composed of equipment host, installation system and electronic control equipment.

QJB type multi-functional spiral submersible mixer can be divided into high-speed mixing submersible mixer and low speed according to its form of action

Push-flow submersible mixer. The high-speed hybrid submersible mixer is divided into direct stamping submersible mixer according to its structural characteristics

And non-direct submersible mixer. Low speed push flow type submersible mixer belongs to non-direct flow submersible mixer.

Hybrid submersible mixer Features:

1. Two independent mechanical seals ensure long-term reliable operation of the submersible motor

2. High quality imported disposable lubricating bearings, designed service life of 100,000 hours, worry-free operation

3. Unique cable seal design eliminates potential cable leakage

4. Stainless steel stamping welded impeller, the blade is swept back after optimization design, high efficiency, with self-cleaning function

5. The motor shaft is made of stainless steel, the rotor is tested by dynamic balance and runs smoothly

6. Internal leakage sensor and group overtemperature protection alarm device

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us