PRODUCTS

1.2 Product introduction of BE series water ring vacuum pump

This series of pumps is a single-stage single action structure, which has the advantages of simple structure, convenient maintenance, reliable operation, high efficiency and energy saving. Compared with the SK, 2SK and SZ series water ring vacuum pumps widely used in China at present, they have significant advantages such as high vacuum degree, low power consumption and reliable operation. They are ideal substitutes for SK, 2SK and SZ series water ring vacuum pumps.

2.2 Product picture of BE series water ring vacuum pump

Application scope of 2BE series water ring vacuum pump

1. The pump can work continuously for a long time under the condition that the ambient temperature is 5~40 ℃ and the inlet pressure is less than 1330Pa.

2. The pump is not suitable for pumping out gases with high oxygen content, toxic, explosive, corrosive to metals, chemical reaction to pump oil, and particles and dust, nor for transporting gas from one container to another as a delivery pump.

3. The continuous working time of the pump under the inlet pressure from atmospheric pressure to 6000Pa shall not exceed 3min, so as to avoid damage to the pump caused by fuel injection or poor lubrication.

4. NSK or NTN original imported bearings are adopted for all bearings, ensuring the precise positioning of the impeller of 2BE1 vacuum pump and high stability during operation.

3.2 Features of BE series water ring vacuum pump

1. The belt pulley (belt drive) adopts standard high-precision taper sleeve belt pulley, which is reliable in operation, long in service life and convenient in disassembly.

2. The coupling (direct transmission) adopts standard high strength elastic coupling, which is stable and reliable in operation and has a long service life.

3. The unique upper gas water separator saves space and effectively reduces noise.

4. Mechanical seals (optional parts) are all standard parts to fully ensure that 2BE series vacuum pumps have no leakage during long operation.

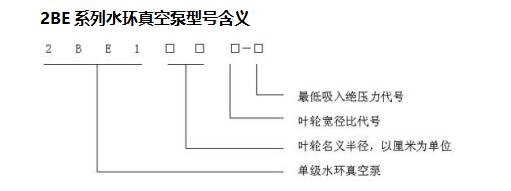

Model Meaning of 2BE Series Water Ring Vacuum Pump

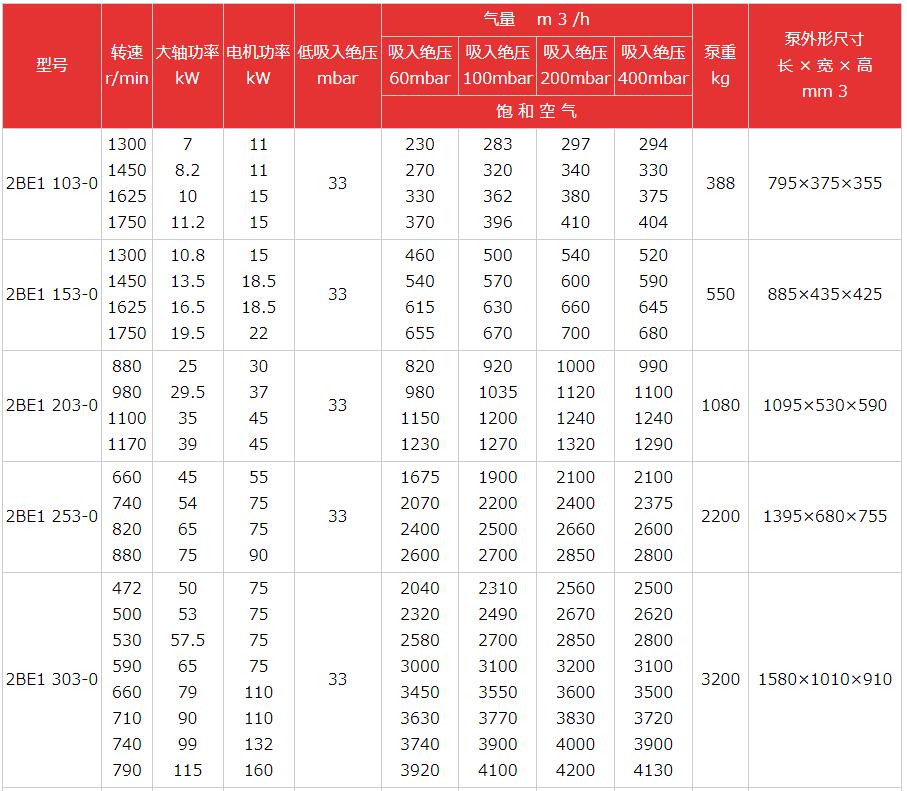

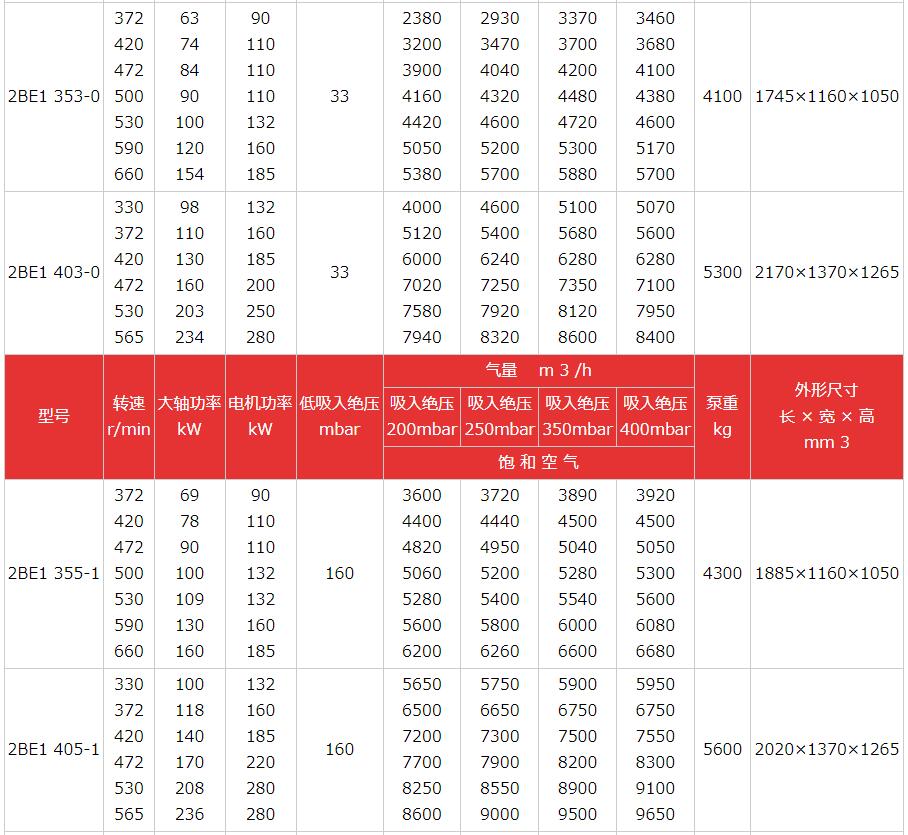

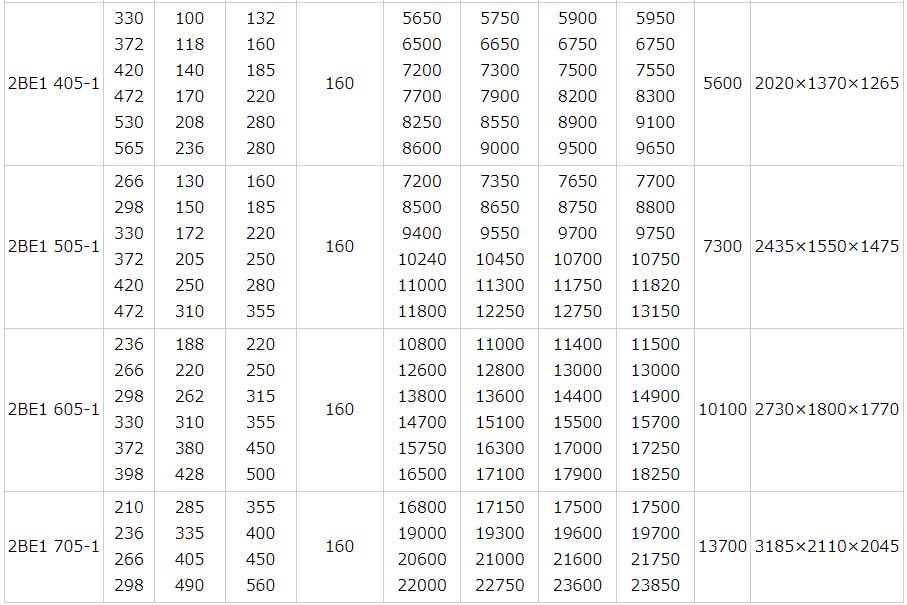

Model Selection Parameters of 2BE Series Water Ring Vacuum Pump

Note: The above performance data are based on the inlet air temperature of 20 ° C and the inlet water temperature of 15 ° C. The exhaust pressure is 1013 mbar.

Operating instructions of 2BE water ring vacuum pump:

1. Start

Before starting, rotate the coupling several turns by hand to ensure that there is no jamming in the pump, and determine whether the motor steering is consistent with the pump steering

, start in the following order.

(1) Close the valve on the air inlet pipe

(2) Start the motor (the pump rotates clockwise from the pump coupling end, the right is the suction port, and the left is the exhaust port)

(3) Open the valve on the water supply pipeline and gradually increase the water supply until it meets the requirements.

(4) When the vacuum pump reaches the limit pressure, open the valve on the air inlet pipe, and the pump starts to work normally.

(5) Adjust the packing gland to make the water drop outward.

(6) When the vacuum pump is working under the extreme pressure, the explosion sound may be generated in the pump due to physical action, and the valve on the inlet pipe can be adjusted

Increase the air intake and the explosion will disappear. If it cannot disappear, check other causes.

2. Parking

(1) Close the valve on the air inlet pipe.

(2) Close the valve on the water supply pipe.

(3) Switch off the motor.

(4) Drain the working fluid in the vacuum pump to prevent corrosion. (To prevent frost cracking in winter)

3. Maintenance

(1) Check the operation and lubrication of the bearing. The operating temperature is 15 ℃ - 20 ℃ higher than the ambient temperature. Up to 30 ° C, and

Add oil 3-4 times a year and clean it once.

(2) The packing seal shall compress the packing regularly. If the packing should be worn and cannot be sealed, the packing shall be replaced. Water leakage of mechanical seal shall be inspected

Check whether the dynamic and static sealing rings are damaged or the sealing rings are aging. Replace the accessories in case of the above conditions.

(3) In case of special sound, remove the pressure plate on the pump cover to check the damage of the impeller face and valve plate.

Disassembly and Assembly of 2BE Water Ring Vacuum Pump

1. Disassembly (2BEA20-25)

Before disassembly, drain the water from the 2BE water ring vacuum pump and remove the separator and connecting pipe. The order of disassembly of the pump from the rear end (the end without coupling) is as follows:

(1) Remove the cover of the bearing chamber, take down the pressure washer, loosen the nut of the bearing chamber, and take down the bearing chamber.

(2) Dismantle the bearing frame, loosen the packing gland nuts, and take down the packing gland.

(3) Loosen the tension bolts and the anchor bolts of the pump cover, and then remove the rear end cover.

(4) Remove the pump body.

(5) Remove the coupling and flat key, loosen and remove the front pressure bearing cover.

(6) Take out the pump shaft and impeller from the front end cover, and loosen the front bearing frame.

2BEA30-35 Disassembly

(1) Remove the rear bearing cover, remove the fastening screws of the locating bearing, remove the adjusting shims, loosen the nuts of the locating bearing gland, and remove the bearing pedestal and the bearing gland.

(2) Remove the packing gland, and take out the stuffing box and packing ring.

(3) Loosen the connecting bolts and take out the pump cover and pump body.

(4) Take down the coupling and front bearing gland, take down the shaft retainer ring with calipers, and take down the oil slinger.

(5) Loosen the bearing gland bolts and take down the bearing pedestal, bearing gland, packing gland and stuffing box in turn.

(6) Remove the impeller and shaft together.

After the disassembly, wipe the mating surface and oil as shown in the figure.

2. Assembly

Wipe off all mating surfaces, apply new oil to the bearing after cleaning, and apply new oil to the bearing seat. The assembly sequence is reverse to that of disassembly. At this time, the position of the impeller in the vacuum pump body should be adjusted. The end clearance is shown in the following table:

Ordering instructions for 2BE series water ring vacuum pump:

I Please provide the following detailed data: ① Product name and model of 2BE water ring vacuum pump ② Vacuum degree requirement unit of 2BE water ring vacuum pump PA or MPA ③ Pumping speed requirement unit of 2BE water ring vacuum pump L/S or M3/MIN ④ Service conditions and work conditions of 2BE water ring vacuum pump ⑤ Motor power of 2BE water ring vacuum pump (KW) ⑥ Rotating speed of 2BE water ring vacuum pump (r/min) ⑦ Voltage of 2BE water ring vacuum pump [ V ]⑧ Inlet and outlet diameter of 2BE water ring vacuum pump ⑨ Whether 2BE water ring vacuum pump is equipped with accessories, so that we can select the right type for you.

2、 If the design unit has selected the product model of our 2BE water ring vacuum pump, please order it directly from the sales department of the company according to the model of 2BE water ring vacuum pump.

3、 When the use occasion is very important or the environment is relatively complex, please provide design drawings and detailed parameters as much as possible, and our technical experts will confirm the model selection for you.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us