PRODUCTS

1、 Product introduction

2X rotary vane vacuum pump is the main equipment to extract the gas in the closed container to obtain vacuum. It can be used for vacuum coating, bulb, thermos, electronic tube, medical treatment, chemical industry, laboratory and other vacuum operations. The pump can be used alone, or as the front pump of booster pump and molecular pump. It is not suitable to pump the gas with high oxygen content, explosive, corrosive to metal and containing particles and dust. The limit pressure can reach 0.06pa.

2、 Product pictures

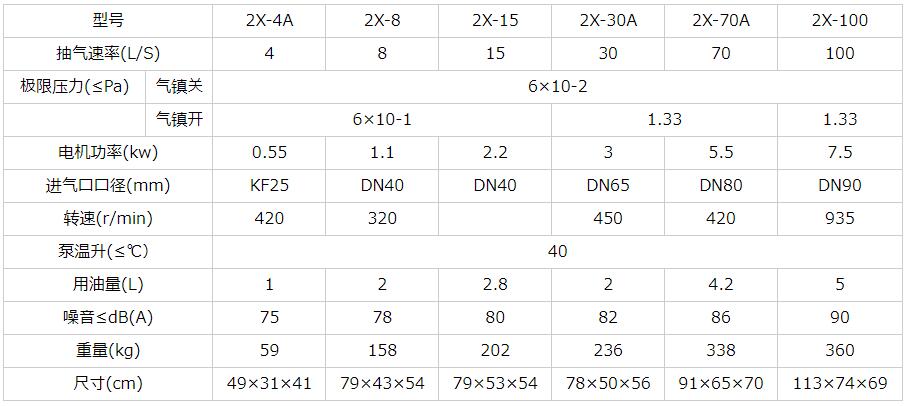

3、 Technical parameters:

4、 Instructions:

1. Precautions for operation of 2X rotary vane vacuum pump:

(1) Start up intermittently for 1~2 times, and observe whether there is abnormal sound and special vibration during operation. If there is no problem, continuous operation can be carried out.

1、 Product introduction

2X rotary vane vacuum pump is the main equipment to extract the gas in the closed container to obtain vacuum. It can be used for vacuum coating, bulb, thermos, electronic tube, medical treatment, chemical industry, laboratory and other vacuum operations. The pump can be used alone, or as the front pump of booster pump and molecular pump. It is not suitable to pump the gas with high oxygen content, explosive, corrosive to metal and containing particles and dust. The limit pressure can reach 0.06pa.

2、 Product pictures

3、 Technical parameters:

(2) Note that the oil level should be between the two oil mark lines of the mirror. Too much oil will cause difficult starting, oil return, fuel injection and other undesirable phenomena. Less oil will affect the vacuum degree. In case of insufficient oil, oil shall be added through the filler hole. Note that the oil level of the pump that has been stopped for a long time should drop, and the oil level will rise only after the pump has been operated continuously for several revolutions.

(3) Turn on the cooling water.

(4) Open the valve on the intake nozzle of the pump, and the opening size depends on the specific situation.

2. For the rotary vane vacuum pump installed for the first time, a test run shall be carried out first. At this time, the pump shall be free from improper installation vibration and special impact sound, the motor shall not be overloaded, and the oil temperature and limit vacuum degree shall meet the technical specifications.

3. When stopping the rotary vane vacuum pump, the valve on the air inlet nozzle shall be shut off first. If the air release valve is installed, the pump shall be vented, the power supply shall be cut off, and then the water source shall be stopped.

4. Precautions for use of rotary vane vacuum pump:

(1) Always pay attention to the oil level.

(2) Slowly open the valve after starting the pump.

(3) Always pay attention to whether the pump operates normally, whether there is any special sound, and whether the motor operates overload.

(4) Pay attention to whether the cooling water is interrupted.

(5) Note that the pump temperature rise shall not exceed 40 ℃

(6) If the temperature of rotary vane vacuum pump drops below 5 ℃ after shutdown, the cold water in the pump must be removed.

5、 Maintenance:

1. In addition to item 15, the 2X rotary vane vacuum pump shall also pay attention to the following items:

(1) The rotary vane vacuum pump must always be kept clean, and no other objects shall be placed on the pump.

(2) Pay attention to whether the belt tightness is appropriate, and adjust it once every half year.

(3) Check whether there is air leakage at the pipe joint and eliminate it in time.

2. The oil of 2X rotary vane vacuum pump shall be changed once after it has been working continuously for three to six months. In areas with high humidity, pumps that work in wet seasons, or pumps that are heavily polluted by gas extraction, the oil change time shall be shortened as appropriate according to the specific situation.

The oil change items are as follows:

(1) Remove the rotary vane vacuum pump from the vacuum system, pad up one end of the chassis motor, open the drain plug to drain oil, rotate the vacuum pump and cover the exhaust port to drain all the dirty oil in the cavity from the oil drain port, then add 100~50ml of new oil from the air inlet and continuously rotate it for more than 5~10 revolutions to clean the interior. Operate this for 3-5 times. After the special dirty oil is drained, install the drain plug, level the pump, and add new oil from the air inlet and filler hole respectively, The oil change is completed.

(2) The motor should not be started for too long during oil change to avoid excessive pulsation and fatigue of the exhaust valve blade.

(3) It is forbidden to clean the pump with kerosene, gasoline, alcohol, etc. without disassembly.

3. If the rotary vane vacuum pump is stopped for a long time, remove the exhaust hood and put on the exhaust plug, close the air inlet and drain off the accumulated water.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us