PRODUCTS

1. Product introduction

ISGB detachable pipeline centrifugal pump is a product with novel structure and advanced technology developed on the basis of ISG pump. This vertical pump, especially in its overall structure, has made a bold breakthrough in design. It uses independent bearing body and pump shaft support to solve the shortcomings of the original vertical pump supported by motor bearings. The impeller and pump body are designed and manufactured using the best modern hydraulic model, eliminating the shortcomings of the original vertical pump with large axial force; Y series standard universal motor is adopted for the motor, which solves the problem of difficult replacement of the original vertical pump extended shaft motor; meanwhile, the 100% removable structure solves the problem of replacing the bearing, mechanical seal, impeller and pump shaft of the high-power pump.

2. Product pictures

3. Scope of application

ISGB detachable pipeline centrifugal pump: mainly used for industrial and boiler system transportation, urban high-rise building water supply, fire pipeline pressurization, HVAC cold and hot water circulation, long-distance water transportation and production process circulation pressurization. TTHB detachable single-stage chemical pump: it is suitable for pressurized circulation of high-temperature hot water for boilers in metallurgy, chemical industry, textile, wood processing, paper making, hotels, bathrooms, hotels, etc., as well as heat supply pumps for urban heating systems.

4. Product Features

1. Vertical structure, convenient for installation and commissioning. The specially designed motor and pump body are connected by connecting body, with concentric height and high processing accuracy. The floor area is greatly reduced, reducing the construction investment.

2. The feet are stable and compact, and the exquisite casting and appearance treatment give the vertical centrifugal pump a new aesthetic feeling.

3. The removable claw type elastic coupling makes the pump start without vibration and noise. The rotating parts can also be equipped with a reliable safety shield with excellent safety.

4. The bearings are precision bearings of international famous brands with high precision, good reliability and long service life.

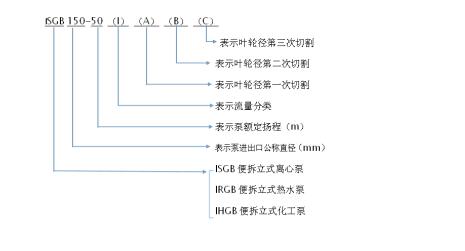

5. Model Meaning

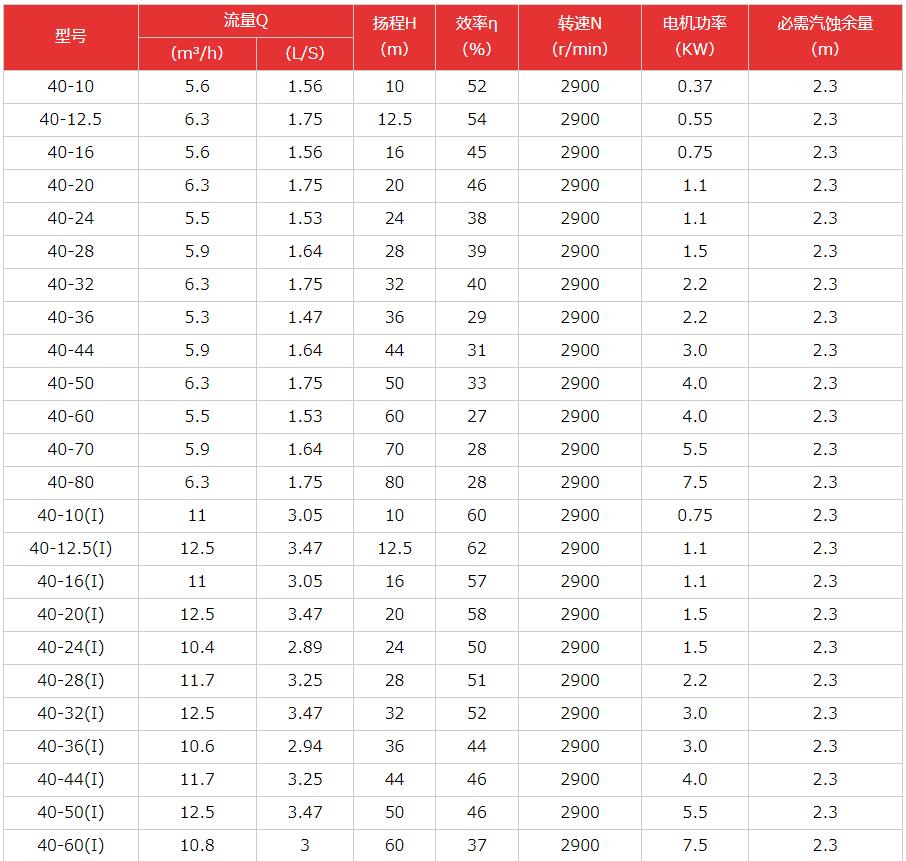

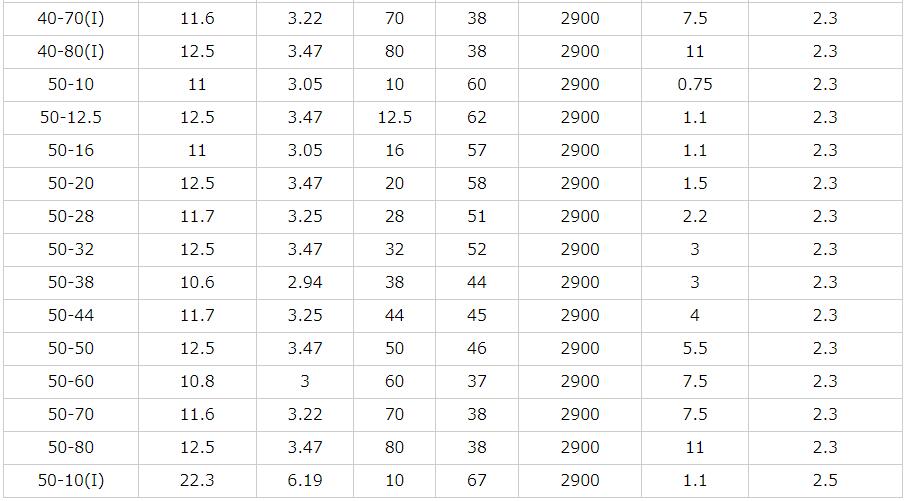

6. Specifications

7. Installation method

(1) The weight of the pipeline shall not be added to the water pump during the installation of the removable pipeline pump, so as to prevent the pump from deforming and affecting the operating performance and life.

(2) It is better to install anti-seismic fasteners on both sides of the pump and between the foundation and the pump body to minimize the possible noise generated by the pump.

(3) The pump and motor are of integral structure, so alignment is not required during installation, so installation is very convenient.

(4) It is recommended to install a filter screen at the pump inlet to prevent blockage.

(5) Sufficient maintenance space shall be reserved for the pump during installation to facilitate equipment maintenance in the later period.

8. Precautions

(1) The removable pipe pump is used for suction, and it should be equipped with a bottom valve. The inlet pipeline should not have too many bends, and there should be no water or air leakage.

(2) Before the first startup, the pump shaft and impeller should be free of friction sound or seizure, otherwise the pump should be disassembled to check the cause.

(3) It is forbidden to work the mechanical seal under dry grinding.

(4) When starting the pump, let the pump exhaust by loosening the exhaust screw on the pump head until a steady flow of liquid flows out of the exhaust hole, and then tighten the exhaust screw.

9. Frequently Asked Questions

(1) The water pump does not absorb water. It may be that the water injected into the pump is not enough,

(2) Insufficient flow of water pump may be due to blockage of water pump, excessive friction of sealing ring and insufficient rotation speed

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly check the pump performance (such as flow, lift, vibration, etc.) and make records. The maintenance items and the interval time between each maintenance depend on the working conditions and operating conditions of the pump.

(2) It is prohibited to operate the pump under cavitation condition for a long time.

(3) It is prohibited to run the motor for a long time with excessive current when the pump is running at large flow.

(4) The medium conveyed by the pump shall not contain air or gas, otherwise, the flow and lift of the pump will not be measured accurately, and the parts will be damaged by grinding.

(5) The suction pipe of the pump shall be as short as possible, the pipe diameter shall be greater than or equal to the diameter of the suction inlet of the pump, and the bending radius of the suction pipe of the pump shall be as large as possible.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us