PRODUCTS

Summary

The electric diaphragm pump is a new type of pumps. In recent years break-through progress has been made in the diaphragm material, so more and more industrialized countries in the world have adopted such a pump type to replace some centrifugal or screw pumps to be appiied in such industries as petrochemicals, ceramics and metallurgy. Our diaphragm pumps include QBY pneumatic and DBY electric types, and all of our product designs are based on reference of the prototypes of American-based ABEL and have been appraised by the Ministry of Coal Industry. DBY diaphragm pumps are applicable for low pressure applications. namely the outlet pressure ≥ 3kgf/cm², whiie QBY applicabie for applications with the outlet pressure ≥ 5kgf/cm². This manual is for DBY disphragm pumps.

Perormanceand Characteristics

DBY series of electric diaphragm pumps has the following characteristics:

l.There is no need for water filling or diversion. and its self-priming capacity is above 7m.

Il. Its trafficability is good, and those grains, slurry or others with a diameter less than 10mm can all be passed easily.

lll.The diaphragm will be separated by the working medium and the transmission machinery. so the medium can by no means leak outwards. Besides, the pump itself has no shaft seal, so its service life is extended greatly. According to different medium types, the diaphraqm can be divided into neoprene, fluorine rubber, chemigum and so on, which can meet requirements of different users completely.

IV.Compact and light: with a planetary cycloid transmission structure, the pump can be small-size, and compared with similar pump types, both of its volume and weight are half or so.

V.The medium flow-through part on the pump body can adopt cast iron, stainless steel, rubber lining or fluorine lining, as required by users, and the motor includes three types: common, explosion-proof and speed requlation. At present the pumps is being used in the following applications.

Main Applications

1.Different kinds of virulent, inflammable or volatile liquids.

2.Different kinds of strong acid, alkali and strong-corrosion liquids.

3.Transporting high-temperature media:150℃.

4.Recovery and circulation of hot water.

5.Loading and unloading of oil tankers, oil depots and oil products.

6.Pumping of pickle, jam, mashed potato, chocolate, etc.

7.Pumping of oil paint, wood gum and pigment adhesive.

8.Different kinds of porcelain glaze, cement grout, mortar and slurry.

9.Different kinds of latex, organic solvents and packing.

10.Pumping of sewage and remaining oil from cabins of oil tankers or barges for cabin emptying.

11.Hops, yeast slurry, syrup and molasses.

12.Pumping of sewage and sediment from shafts, adits, tunnels and sewer culverts.

13.Suction and transportation of different kinds of special media.

Working Principle Diagram

The motor (3) drives the diaphragm (2) on the plungers on left and right ends through the reducer (4) to make reciprocating motions from left to right. Inside the left and right pump cavities, there are four upper and lower non-return ball vaives (1) making motions to change volumes of the working cavities and drive the four non-return ball valves to open and close alternately, thus sucking (5) and discharging (6) the liguid continually.

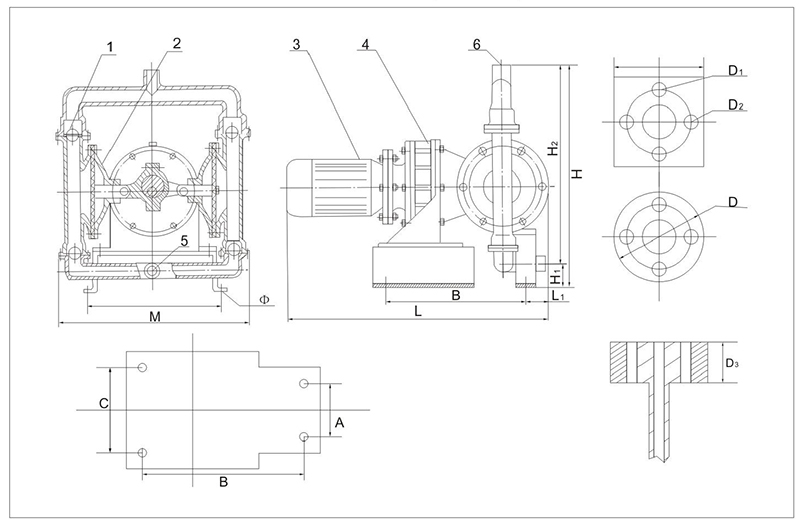

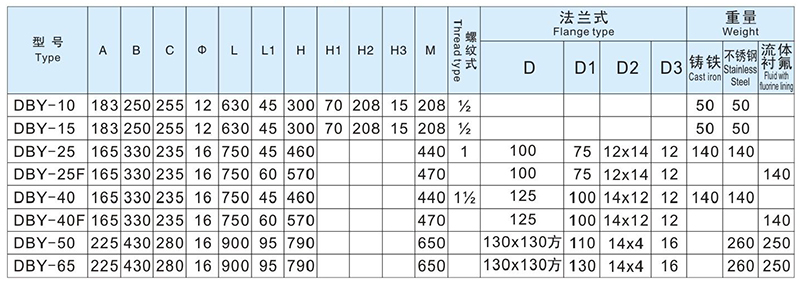

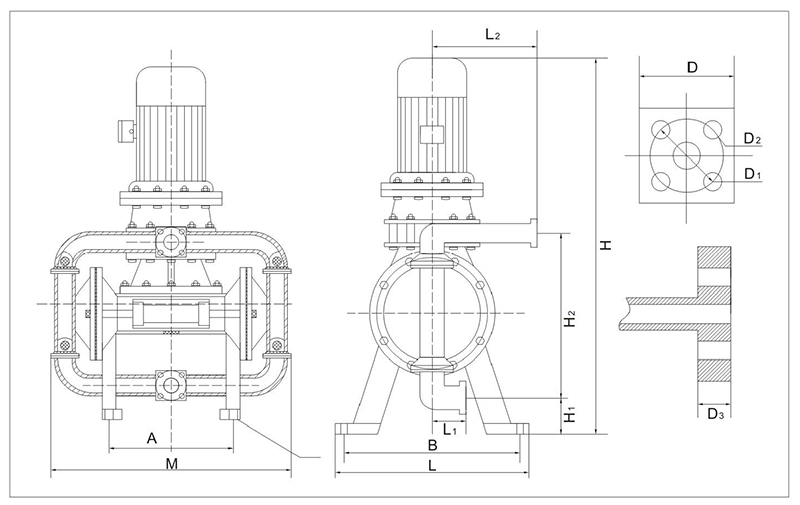

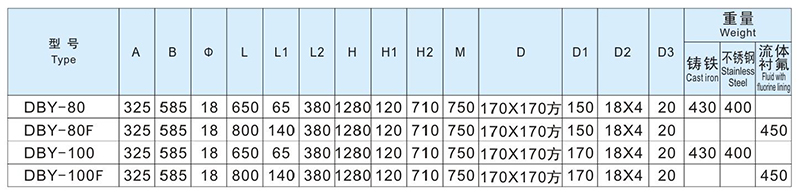

Installing and Overall Dimensions

Installation Dimension Diagram

Installing and Overall Dimensions

Specialnotes

(1)Oil bearings and piston shafts;

(2)The outlet pressure shall not exceed 0.3MPa

(3) It's prohibited from installing any valve at the outet:

(4) In pumping of media vulnerable to being frozen, the media inside the pump body shall be emptied and washed away after use to avoid damages.

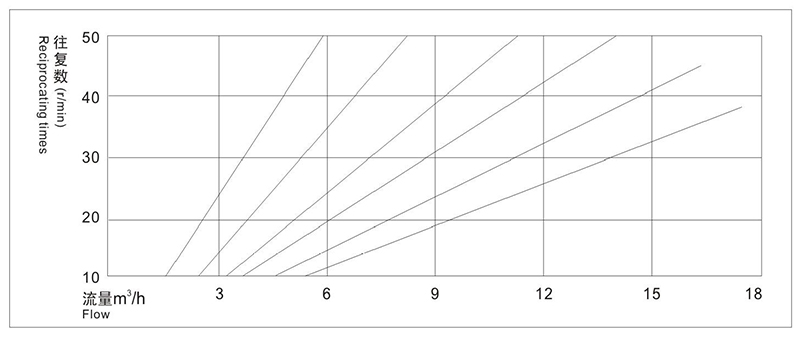

Characteristic Durve Diagram

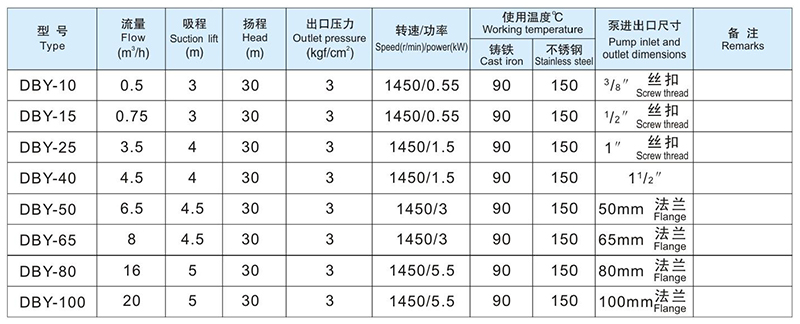

Key Properties and Specifications

Select the Diaphragm COrrectly

The diaphragm is a major part of this diaphragm pump and correct selection of the diaphraam can get twice the result with half the effort. The users shall note nature of their working medium in their orders so as to provide appropriate diaphragms. Generally the diaphragms include the following types:

I. Butyronitrile diaphragm, mainly for oil-proof applications.

II.Neoprene 5031#, specially made by our company, mainly for resistance to acetone and different kinds of acid and alkaline

Ill. Fluorine rubber 6021#, specially made by our company, mainly for high temperature 150℃ and resistance to methylbenzene and corrosion, but more expensive than other diaphragm types.

IV. Food rubber exclusively for transportation of food and beverage.

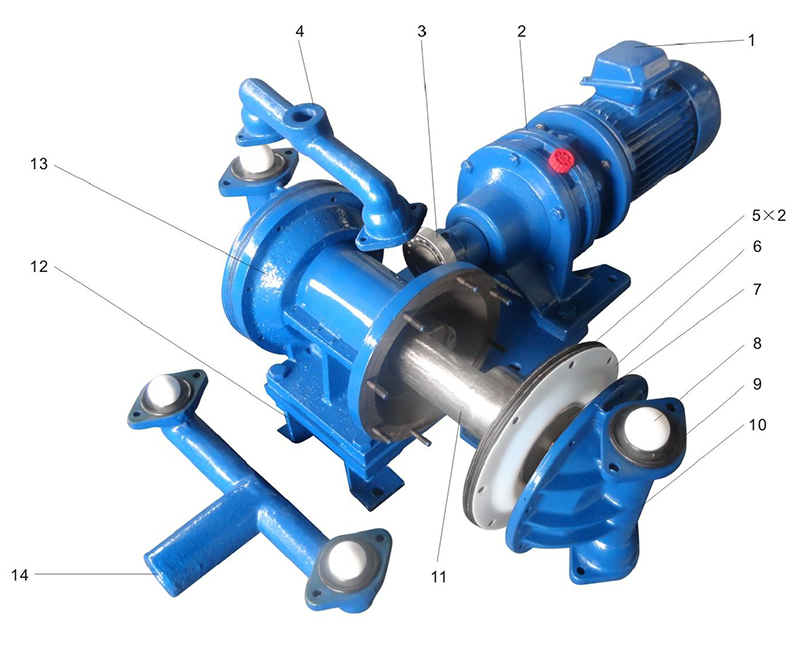

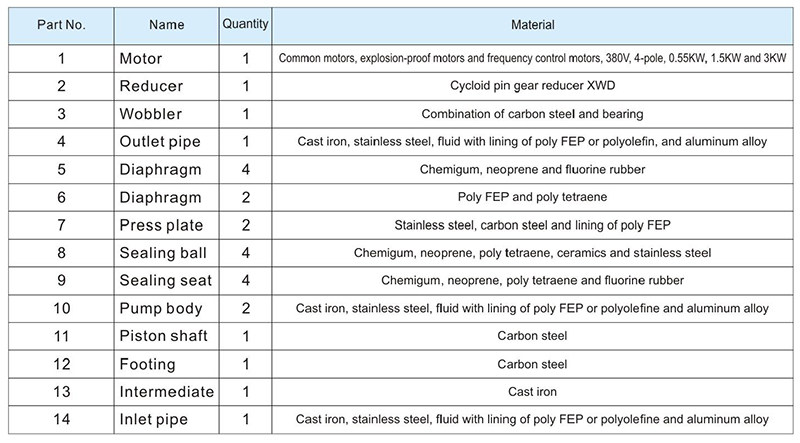

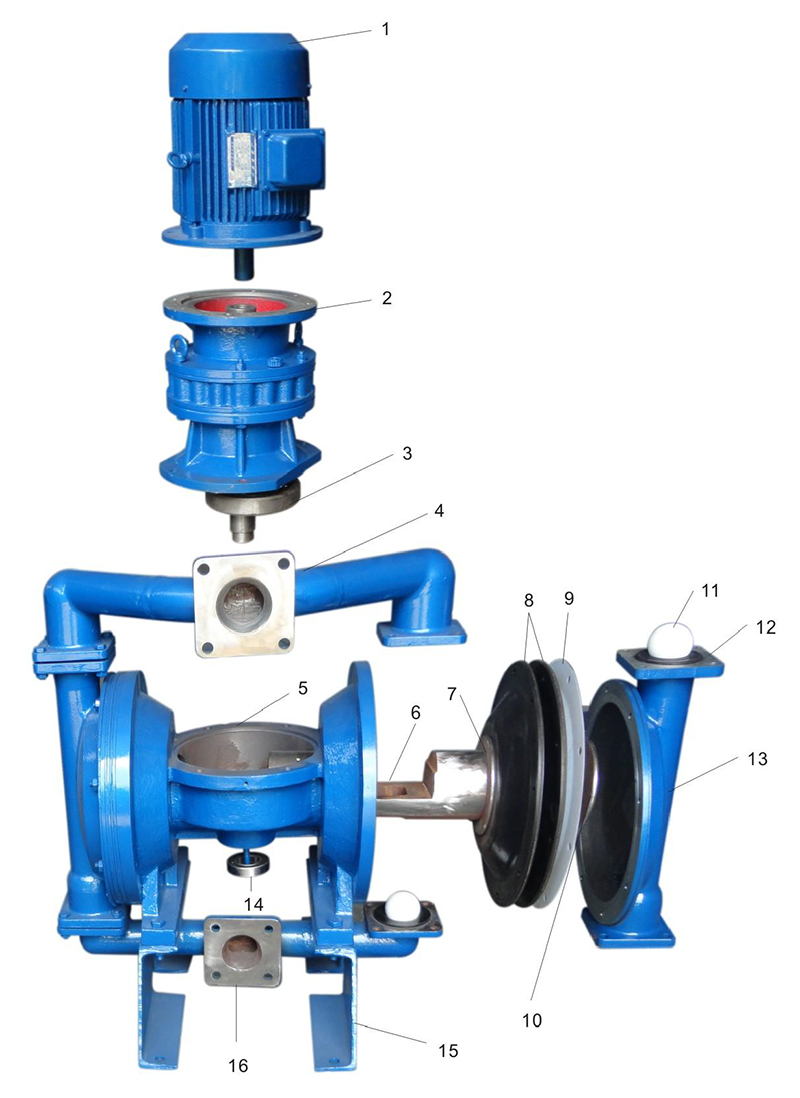

Structural Diagramof DBY - 15 - 25 - 40 - 50

Listof Major Partsof DBY - 15 - 25 - 40 - 50

Structural Diagramof DBY - 80 - 100

Structural Diagramof DBY - 80 - 100

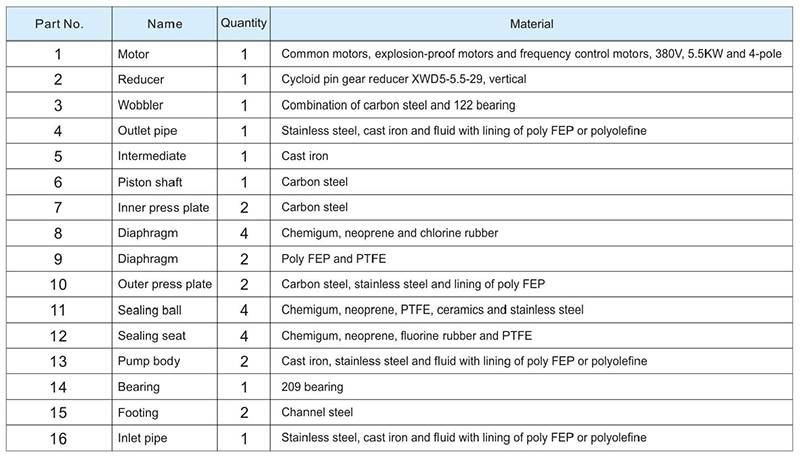

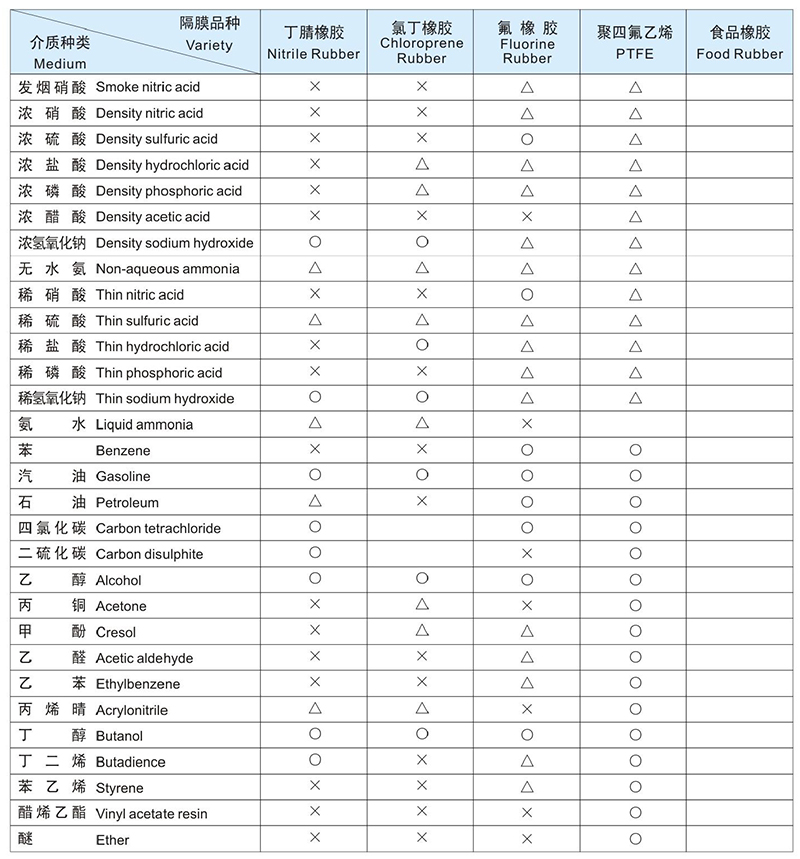

Characteristicofdiaphragm

Note:○-means the long service life, △-means common service lifex, ×-means use forbidden. This table is only considered from the anti-corrosion. Because the PTFE elasticity is worse than that in rubber. The actual use life will be affected because of the pressure and pump stroke factors. The food rubber specially uses for beverage industries.

- DYB Portable Vane Pump

- HWQB Explosion proof Submersible Pump

- HW Adblue/Methanol Pump Series

- KCB Gear Oil Pump

- KYB Self-Priming Vane Pump Series

- LPG Liquefied Gas Pump

- WCB Portable Gear Pump

- Pipeline Pump Series

- Explosion-Proof Motor Series

- Diaphragm Pump Series

- Flowmeter Series

- Oil Drum Pump Series

- DC Pump Series

- Magnetic Pump Series

- Chemical Pump Series

- Centrifugal Pump Series

- Vacuum Pump Series

- Metering Pump Series

- Rotor Pump Series

- Multistage Pump Series

- Sanitary Pump Series

- Screw Pump Series

- Oil Gun And Small Flow Meter

- Explosion-proof type control cabinet

Scan the code to follow Facebook

Phone/wechat/whatsapp: 15868545868 18968868555

Email: haiwan@haiwanpump.cn

Http: www.haiwanpump.com

Add: Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Scan The Code To Contact Us